2.6 Sulphur Dioxide or Preservative Free?

|

| Sulphur occurs uncombined in volcanic and sedimentary deposits. In wine making, it's used in gaseous or powdered form for its dual properties as both an anti-microbial agent and anti-oxidant. Some believe more careful wine making practices would make it redundant, yet it's still added to most wines today and its impact on health remains controversial. |

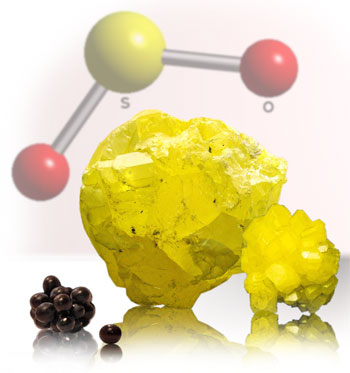

Sulphur is an abundant, pale yellow, brittle, crystalline element that has been significant for its effectiveness as a cleaning agent since antiquity. The association probably began when ores containing sulphur were burned. It then forms the chemical compound, sulphur dioxide (SO2) - a simple molecule of two oxygen bonded with one sulphur, making for a dense, non-flammable, colourless gas which is soluble in water and has a pungent and suffocating smell of burnt matches, often accompanied by an irritation of the membranes of the nose. In the food and wine industries (where its presence is declared on labels as numbers ranging from 220-228),* its properties as an antiseptic and antioxidant have been universally recognized.

Just like food, grape juice is susceptible to the effects of oxidation and microbes from the point of harvest until bottling. Without a defense, irreversible and undesirable changes take place in wine. These can range from a reduction of varietal aroma and flavour to the development of bitterness, vinegar, nail polish remover and sherry-like smells, even the browning of a wine's colour.(1)

Vintners have been developing preservation strategies since ancient times, however, the turning point for sulphur was in 1487. A Prussian Royal decree officially permitted its use for the first time via burning a blend of powdered sulphur, wood chips, herbs and incense inside wine barrels. SO2was then absorbed by the wine once the barrel was filled. Sulphur had of course been used before this time to help preserve wines during transport - Dutch and English wine traders regularly burnt sulphur candles inside barrels before filling them. It was a technique that was probably first handed down from the Egyptians, passed onto the Greeks then the Romans, all of whom reputedly conducted the same practice over a milennia before in order to clean wine amphorae. Later, barrels in Bordeaux would be routinely fumigated in the same way.

Nowadays, sulphur is usually purchased by winemakers in gaseous form (sulphur dioxide) and directly fed into the wine from a dosing gun, or applied as a powder (potassium metabisulfite) that's readily soluble in water or grape must. Dissolved SO2is present in a finished wine in the form of sulphites ('sulfites',if you're American). Deciding when and how much sulphur dioxide to add depends on what stage of winemaking the wine is at and what style of wine one wants to produce. There are no text book rules on the quantity of SO2that's added. A winemaker might introduce about 30-50 mg/l to grapes at the crusher but double that amount if they notice rot, which imparts oxidative eznymes.(2)Too much SO2creates its own problems - it becomes detectable as an unpleasant aroma in white wines similar to that of a recently struck match, sometimes accompanied by a prickling sensation. Excessive sulphur can also kill the yeast that performs fermentation or stop malolactic fermentation from completing, producing wines that taste unfinished.

The timing of SO2additions is at a winemaker's discretion, though typically there are five points in the production of dry table wines when it can be employed. The first isduring harvest, when the potential for premature spoilage of the freshly harvested fruit is high. This is especially the case if berries have been damaged by birds, weather or fungi and indiscriminately picked, because the growth of undesirable organisms begins as soon as the juice of the berry is exposed. At temperatures above 10 C (at which most Australian harvest will occur) organisms can rapidly multiply. Sulphur can be applied to picking bins in the form of potassium metabisulfite dust (approx 50 ppm) in order to inhibit the action of wild yeasts and other micro-organisms and prevent oxidation of any juice that may accumulate at the bottom of the bins. This precaution also means the grapes don't have to be rushed to the winery.

Once the grapes arrive at the winery, they're transferred into a crushing machine (or sometimes a press) which opens the skins of the grapes to make the juice more readily available for the yeast to ferment. Wild yeasts and many bacteria are particularly sensitive to the effects of SO2whereas cultured yeasts have been developed to be resilient, so the addition of sulphurat the crusher (30-100ppm) can give the winemaker more control in ensuring a fast, efficient and clean ferment.

During primary fermentation, some of the SO2 that was added at the crusher stage is depleted, having oxidised, vapourised or bonded with components in the wine. Generally, this is a desirable state, especially given that the next step for most full bodied whites and most red wines is malolactic fermentation, in which bacteria convert tart malic acid into creamier lactic acid. Malolactic bacteria are extremely sensitive to sulphites, so if SO2 is added, it's at extremely low levels, around 15ppm.*"...oxidation due to low sulphite levels isn't a problem at this stage because malolactic bacteria generate a blanket of carbon dioxide that essentially seals off the wine from oxygen."(3)Of course, not all wine styles benefit from a malolactic fermentation, so when a fruitier, crisper style which retains malic acid is desired, such as with many Rieslings, enough SO2 will be added (30-80ppm) at the end of the primary fermentation to stop bacteria from performing an untimely (and unwanted) malolactic ferment.

A further 20-30ppm SO2 may be added duringmovements of the wine which might expose the juice to increased oxygen contact, such as during the topping up of barrels or when stabilising the wine's appearance via racking or filtration.

A final addition usually occurs just prior to bottling. At this stage, approximately 15ppm+ is added to prevent oxidation or any other microbial action in the bottled wine. In late-harvest, sweet wines much higher quantities need to be added because sugar tends to bind with sulphites minimising its anti-microbial potency.

Considering the above scenario, total SO2 additions could conceivably vary between 160 and 250 ppm during winemaking. However, by bottling time, the measurable free SO2 may amount to only 30-40 ppm in a dry white wine and 15-25 ppm in dry reds. (4)The reasons for this are several, though primarily it's because winemakers distinguish between "free" and "total" sulfites.

Once mixed into the juice, SO2 takes on several forms. A large proportion of the sulphur dioxide gradually reacts or bonds with around fifty other wine constituents such as sugars, acetaldehyde, and phenolic compounds to form what's known as 'bound' sulphur dioxide. In this form, it is not free to provide antimicrobial or antioxidative protection. (5)Only the remaining "free" or unbound sulphur dioxide remains active in it's ability to effect yeasts, bacteria and potential oxidation. The combined amounts of free and bound sulfites are called 'Total SO2'. Knowing both the amount of free and total sulfites is important because only the free forms of sulfites are available for providing a preservative role in wine - these numbers can readily be determined by chemical analysis."...Most wines get bottled with about 25 to 40 milligrams per litre of free sulfites. The level of total sulfites is usually about double that".(6)

It should be noted that the free portion of SO2 also consists of two parts: one is relatively inactive 'bisulphite' (the bisulfite ion, HSO3), and the other smaller part is the active or 'molecular SO2'. The size of of this latter portion depends on the wine's pH and temperature. We discussed the significance of pH to a wine's colour in chapter 3.3 Wine Colour & the Limits of Visual Assessments. Essentially, pH is a term that quantifies the acidity of a solution. For us, it is describing the acidity of wine. A final pH of about 3.4 - 3.5 generally provides the most balanced flavour for red wines; optimal pH for white wines is slightly lower.

Low pH has several important effects, which include making sulphur dioxide more effective as an antimicrobial agent. That is to say, in high acid environments, more of the added SO2 is free to inhibit spoilage. Consequently, less SO2 will need to be added. In fact, pH has a ten fold effect on the equilibrium between free SO2 and its bisuplhite form. At a pH of 3.0, 6% will be in the form of free SO2. But at a pH of 4.0, only 0.6% will be in the form of free SO2. This further highlights the importance of pH to viticulturalists and wine makers. Poor viticultural practice and high pH values mean excessive use of sulphur dioxide; conversely, wines with sufficient acid will require less.

Preservative Free Wines

Along side sulphur dioxide's role as a preservative is it's potential to cause violent allergic reactions. Those susceptible report headache and bodily discomfort including face flushing, feeling poorly overnight and the following day, even though amounts ingested may have been miniscule. About 5% of asthmatics will experience bronchial constriction that's so severe it can be life threatening. At first SO2 was thought to affect an insignificant percentage of the population but in 1984, Australian researchers found that more than 65% of asthmatic children were sensitive to sulphites, and in 1999 the conservative World Health Organisation (WHO) revised upward their estimate of the number of sulphite-sensitive asthmatic children from 4% to 20-30%. Since then, food regulators have been working slowly to reduce the use of large amounts of sulphite preservatives and the wine industry has followed suit.** In fact, as Peter Gago observes"...a major wine making objective is to minimise its use".(7)

When compared to the maximum sulphite levels permitted in Australia for other common foods and beverages, wine today contains relatively low degrees of SO2, as illustrated by the sample below. |

One part per million (ppm) is equivalent to 1 milligram of a substance per litre of water (mg/l) or (mg/kg). |

| Alcoholic beverages | ppm |

| Wine, sparkling and fortified, >35g/L sugar | 400 |

| Wine as above, < 35 g/L sugar | 250 |

| Wine (fruit, veg, mead), > 5g/L sugar | 300 |

| Wine as above, < 5g/L sugar | 200 |

| Mixed alcoholic drinks | 250 |

| Beer | 25 |

| Beverages, non-alcoholic | |

| Fruit juice, drinks, soft drinks, cordials | 115 |

| Baked goods | |

| As a dough conditioner | 60 |

| Flour products incl. noodles and pasta | 300 |

| Biscuits, cakes and pastry | 300 |

| Processed fruits and vegetables | |

| Candied fruit and vegetables | 2000 |

| Dried fruit (in fruit bars etc) | 3000 |

| Desiccated coconut | 50 |

| Mixed dried fruit (in cakes) | 3000 |

| Imitation fruit (eg cherries) | 3000 |

| Apples and potatoes for manufacturing | 200 |

| Fruit and veg preparation for manufacturing | 1000 |

| Avocado pulp, frozen | 300 |

| Carrots, dried (in cake) | 3000 |

| Dried vegetables | 3000 |

| Potatoes (hot chips, French fries) | 200 |

| Meat | |

| Deli meats | 500 |

| Sausages and sausage meat (raw) | 500 |

| (sulphites are illegal in minced meat, yet it often contains as much or more than sausages) |

|

With the exception of sulphite sensitive asthmatics (around 2% of the population), very few people react to sulphur in the quantities that it's found in wine in Australia. Adverse effects attributed to consuming wine containing sulphites in most cases are probably unwarranted. The common complaint that"wine (or certain kinds of wine) give me a headache etc", is likely to be more often due to intolerance to alcohol rather than any additives that might be in the wine.(8)

The joint FAO/WHO Expert Committee on Food Additives in 1974 established an acceptable daily limit of 0.7mg per kg of body weight. This translates to 56mg for an 80kg individual (0 .056grams). (The lethal intake is defined as 1.5g/kg of body weight) A 750ml bottle of wine containing 150 parts per million sulphites contains 0.225grams. On that basis the daily allowance is met by consumption of 187 mls of such a wine. Most wines are released for sale several years after bottling. After three years in bottle the sulphite level in a white wine may drop by half at which time, twice as much wine may be consumed without exceeding the daily allowance. Red wines start their bottle life with perhaps half the level of sulphite as a white wine and may also be consumed in twice the quantity. (9)The oxygenation of a wine before consumption - which can be done by simply swirling the glass - is reported to free approximately 30-40% of the SO2.

Should wine lovers be worried about sulphur dioxide at all then?

Erl Happ of Happ's Wines in Margaret River, Western Australia believes there is still cause for concern.

An overwhelming majority of the world's winemakers would say "No": Without sulphur it's extremely difficult, even impossible to make top quality wines, let alone wines that can withstand transportation and long term cellaring. It is possible to make wine successfully without using SO2, but this allows less control and results in reduced ageability, consistency and biological stability.Or does it?

Today, more and more winemakers are consciously moving towards an absolute minimal use of SO2. Still others have been successful in removing it from the winemaking process altogether. *** One vigneron at the forefront of experiment and research is Erl Happ. In 2006 he wrote a paper for a Natural Preservatives seminar in Amsterdam titled "Is it Possible to make Attractive Wines Without Sulphur Dioxide?" in which he outlined the circumstances and experiments that led him to create completely sulphur free wines.

"Much hinges on deciding whether the suppression of oxidation and unwanted bacterial activity after ferment can be achieved by means other than sulphite addition", he writes."When you begin to ask questions of this sort, you are well on the way to making a preservative free wine... It is a product of common sense, observation, thinking things through rather than following a recipe book and a willingness to take risks. It is the sort of activity that an owner/winemaker can indulge in that might be regarded as too risky by an employee ... It is possible to produce superior wines using very little[SO2]or none at all...The armory of tools at a wine makers disposal to achieve that end include hand harvesting, inert gases, temperature control and judicious filtration."(10)

Happ has demonstrated this in practise: His successful 'PF' wines rely upon the following protocols:

2. hand harvesting to avoid fruit damage

3. transporting in small containers to avoid crushing the fruit

4. relatively high alcohol 14%

5. abundant tannin

6. pH antagonistic to spoilage organisms

7. optimising conditions for a clean ferment

8. cool temperatures in conservation (Happ chills fruit prior to crushing)

9. deprivation of substrate that would support micro-organisms

10. deprivation of nutrient

11. deprivation of oxygen during conservation

12. close filtration prior to bottling as a security factor

13. extraordinarily careful winemaking techniques

Happ also emphasises that a preservative free mind set must start in the vineyard."...due to climatic circumstances in Margaret River and Karridale in particular, we begin with very good raw materials...our grapes have naturally high phenolic content, a natural antioxidant. This is due to the fruit having a greater exposure to sunlight in turn due to our dual row trellising system that disperses the foliage to a much greater extent than other systems of viticulture, especially the more restrictive systems designed for mechanical harvesting". A technique to keep the juice cold for long periods and away from air has also been developed."None of this is rocket science!"reassures Happ."But it is more costly."(11)

For Happ, sulphur dioxide is overrated as 'the preservative' in wine. Rather,"The natural preservative in wine is alcohol, tannin (phenolics) and natural acidity...The aging capacity of wine after bottling is conditional on its depth of flavour, freshness at bottling, the bottling technique, container type, closure type, the presence of fermentable substances and the presence of organisms capable of degrading the wine. Unless these latter conditions are met, no amount of 'added preservative' will assist. If these conditions are met very little if any added preservative is required."(12)

A notable producer who goes some way to substantiating Happ's argument is Laurent Ponsot in Morey St.Denis, Burgundy, France, whose Pinot Noirs frequently command stratospheric prices. For Ponsot, the large amounts of CO2 produced by fermentation are sufficient to protect the must against oxidation. During elevage, barrels are kept filled so as to avoid exposure to oxygen; and at bottling the wine is kept under carbon dioxide or nitrogen. In fact, since 1988, SO2 has been used only twice during production, the most recent case being the 2003 vintage when high levels of volatile acidity resulting from the vintage conditions required small doses of SO2 to control.

"The results are as distinctive as the methods, but also profoundly impressive and proven to age magnificently"comments American Wine writer, Robert Parker. "...At their finest, Ponsot's wines are classic examples of great red burgundy. While rich and accessible enough to be drunk young, they are capable of lasting 20-30 years, making Ponsot one of a handful of Burgundy growers committed to making long-lived wines."(13)

Cognisant of the increasingly negative perception and health concerns consumption of SO2poses, viable substitutes are being pursued in some unusual directions. Spanish researchers have found using ozone to keep grapes fresh was 90% as effective as sulphur dioxide. What's more, the ozone-treated grapes had up to four times the antioxidants than untreated grapes.(14) An alternative product of biological origin containing mainly black radish(raphanus niger)extract and ascorbic acid has been successfully tested by Greek wine researchers. While the new additive may not lead to the replacement of SO2, the researchers noted it could at least lead to its partial substitution.(15) As more and more consumers seek natural alternatives to synthetic or "chemical" additives in food and wine, the issue of sulphur dioxide seems certain to re-invigorate a centuries old debate into what remains one of the most contentious issues of modern wine making.

220 Sulphur dioxide

221 Sodium sulphite

222 Sodium bisulphite

223 Sodium metabisulphite

224 Potassium metabisulphite

225 Potassium sulphite

228 Potassium bisulphite

** As an indicator, permitted levels in wine circa 1910 were up to 500ppm.

*** It may surprise some readers to learn that sulfites are formed naturally during primary fermentation (more so in whites than reds) - a fact that has sometimes been used by the industry to defend the use of sulphur dioxide. The quantities produced are thought to be dependent on the yeast strain used. Regardless, in the vast majority of cases these quantities are insignificant (<10ppm) in comparison to those added during the wine making process. Some studies have found them to be non-existent.

1. Australian Wine. From the Vine to the Glass. Patrick Iland & Peter Gago. Patrick Iland Wine Promotions, Australia 1997.

2. Inside Wine: Sulfites. Daniel Sogg, Wine Spectator Magazine, February 2003.

3. Ibid

4. Is it Possible to make Attractive Wines Without Sulphur Dioxide?" Erl Happ, Happs Vineyard. December 2006

5. Oxford Encyclopedia of Wine, 1994 Edition

6. Inside Wine: Sulfites. Daniel Sogg, Wine Spectator Magazine, February 2003

7. Peter Gago is a noted Australian winemaker and educator.

8. As suggested by Max Allen, Whine reaction, November 2004, CPA Australia

9. www.happs.com.au

10. Is it Possible to make Attractive Wines Without Sulphur Dioxide?" Erl Happ, Happs Vineyard. December 2006

11. Some Notes on Sulphur Dioxide and the Happs Approach to Making Wine with Very Little or no Sulphite at all). Erl Happ, December 2006. See www.happs.com.au

12. Ibid

13. Robert Parker, The Wine Advocate, April 2007, http://www.erobertparker.com

14. Allergy hope over wine preserver. Monday, 12 February 2007. BBC News Channel. http://news.bbc.co.uk

15. Source: Journal of Food Composition and Analysis. December 2008, Volume 21, Issue 8, Pages 660-666 "A natural alternative to sulphur dioxide for red wine production: Influence on colour, antioxidant activity and anthocyanin content" Authors: M.-I. Salaha, S. Kallithraka, I. Marmaras, E. Koussissi, I. Tzourou