2.14 Corks & Cork Taint

|

| Above: Three views of cork: At the rear, the first microscopic illustration of cork which also introduced the concept of the 'cell' to science. In the middle ground, cork bark in its natural state, and in the foreground, the product now so familiar to wine lovers |

We introduced this section on wine making with an image of the oldest wine jar in the world and considered wine making at its most elemental, imagining primitive man's experiments with wild grapes and crude vessels that could be sealed to prevent oxidization. Most of early wine making history could well be interpreted from the perspective of man's attempts to control air. This last, but crucial consideration returns again and again, and continues to inspire innovation. For the final seal is not only the guardian of a wine maker's creation, it is also key to the arising of new dimensions of flavour over time.

The stopper that has become synonymous with wine for the last three centuries is of course, the cork. In his pioneering work into microscopy, Robert Hooke (1635-1703) included amongst his botanical observations the first description of the honeycomb-like structure of cork, which he described as being composed of "cellulae", thereby coining the modern biological usage of the word "cell" to describe the basic microscopic units of tissue.* On average, each cubic centimetre of cork contains 40 million cells, while one cork stopper contains around 800 million cells. Why the cork is so perfect as a closure is largely to do with cell wall deformation. When a cork is inserted into the bottle, the cell walls buckle, giving large recoverable deflections and large energy absorption.(1)

Around 45% of the cell walls of a cork are composed of the complex acid, suberin, a waxy substance filled with a mixture of gas almost identical to air, responsible for elasticity. Polysaccharides in the cork walls (12%) help define the texture of the cork. Other properties include lignin (27%) - an insulating compound, tannins (6%) responsible for colour; seroids (5%) hydrophobic compounds that guarantee the impermeability of the cork, and in minute quantities, substances such as ash, mineral water & glycerine.

The cell structure and chemical composition of cork combined, endow it a unique and remarkable position amongst natural materials. Most noticeably, it is both elastic and compressible - it reacquires its original form after undergoing pressure recovering about 85% of its initial volume almost immediately, and more than 98% after 24 hours. Less discernible are a host of other qualities,

|

| Above: Cork Cells Magnified 100x |

|

| Above: Cork cells magnified 400x Source: David B. Fankhauser, Ph.D., Professor of Biology and Chemistry, University of Cincinnati, Batavia OH |

ranging from impermeability to liquids and gases, lightness and buoyancy to adherence (the slicing of surface cells means that millions of cells are opened to function as suction cups, providing an exceptional power of adhesion to wet, smooth surfaces). Cork also makes excellent thermal, acoustic and anti-vibratic insulation; It does not absorb dust thus preventing allergies, and it is fire resistant and retardant.(2)

A remarkable list of properties indeed, to which should be added being easily cut into forms. Yet even given all the advantages of the material, cork and wine were for a long time little more than intermittent companions. Why this was the case is not completely certain. Clearly it was not due to ignorance: Cork was already being used with fishing tackle in China, Egypt, Babylon and Persia around 3000 BC. In Italy, remains dating from the 4th century BC have been found that include cork artifacts such as women's footwear, fisherman's life jackets, roofing and flooring materials as well as stoppers. And from the same period we gain one of the first glowing references to the cork oak, by the Greek philosopher Theophrastus who, in his botanical treatises, described with wonder"...the ability that [the cork] tree has to renew its bark after it has been removed".**

More substantial evidence of corks being used as stoppers exists in the form of amphorae found in Pompeii and Ephesus. The latter from the 1st century BC had not only been sealed with a cork stopper but still contained wine, evidence which is in turn countered by Pliny whose writings indicate that such stoppers were relatively uncommon. Romans preferred pitch, clay, gypsum or potters earth to seal vessels, and the technique of filling the upper part of a vessel with oil or honey, which would float on top of the liquid forming a protective cap.(3) After the Roman Empire and throughout the Medieval period, the use of cork as a stopper seems to have been completely abandoned. It has been postulated that this was because the main supply route was via the Iberian Peninsula which had been conquered by the Moors in the 8th Century. Paintings from that era depict twists of bung and cloth or leather being used, sometimes with sealing wax to make an air-tight closure.

One reason for the scarcity of cork stoppers must be that during certain periods, large earthen vessels with wide mouths were prevalent,"...which could not be stopped sufficiently close by means of a cork." (4) Put simply, a vessels design must determine its closure. While cork can compensate for small imperfections in glass, its success ultimately depends upon its fitting snugly into an opening with a relatively smooth uniform diameter. In the West at least, technology did not catch up with the cork until the 17th century when glass making advanced to the point that more or less uniformly-sized bottle necks could be consistently produced. This permitted the marriage of bottle to cork stopper and the development of these two elements are generally credited as the two necessary prerequisites for the modern international wine trade.

The man responsible for taking the first step towards the most widespread use of cork as the wine closure we know today, also has a permanent place in Champagne history: The 17th Century Benedictine monk, Dom Perignon. At the cellars of the Abbey, Hautvillers in Epernay containers holding sparkling wine had traditionally been plugged by wooden stoppers wrapped in olive oil soaked hemp which often popped out. Inspired by the cork-sealed pots of pilgrims from Compostela, Dom Perignon successfully swapped the conical plugs for cork stoppers.

|

| Bottle with old style cork and wire tie down. |

But as with any new technology, cork had to prove itself to the market place before it gained acceptance. In the interim, glass stoppers (or 'stoppels') were still being used whereby the stopper and the inside of the bottle were ground using emery powder and oil to create a perfect glass to glass seal. The drawbacks with this procedure were firstly expense. To achieve an effective seal a tool must be made that perfectly matches the chamber of the stopper and glass neck. Further, to transport the bottles, the stoppers must be tied down by string or firmly twisted to prevent the stoppers vibrating loose which in turn often made them difficult or impossible to extract without breaking the bottle. In spite of this, glass stoppers held their own for a remarkably long time, an attitude reflected in Worlidge's "Treatise of Cider," (1676) in which he declares that great care is needed in choosing good corks,"...much liquor being absolutely spoiled through the only defect of the cork. Therefore are glass stoppels to be preferred..."(5)

In the first half of the 18th century, the obvious benefits of cork stoppers with glass bottles, further consolidated by ongoing advances in glass making techniques in England saw to the cork stopper being used by prestigious wine producers like Ruinart de Rheims (the first Champagne house) and Moët et Chandon. Initially the corks were fashioned so as not to be fully depressed into the neck of the bottle. This was primarily due to the fact that cork screws were not yet invented and that hand-blown bottle neck sizes varied. One's fingers simply gripped the top of the cork and pulled it out (a set of teeth were probably more common to the task).

| VIDEO: Corks - Historical overview. |

The growing demand for the cork closure gave rise to the creation of the first cork stopper factory in Catalonia in 1750. Cork stoppers were initially made from cork blocks (cork parallelepipeds), already cut to the length of the final product. These were called "reproduction" stoppers and were produced by a circular cut in the cork block using a burro (knife). In the 19th century, France, Italy and Tunisia invested in the systematic planting of cork forests. It was a century marked by significant developments in the industry: in the United Kingdom the first cork stopper manufacturing machine was patented, and auxiliary equipment was invented, such as cork stopper counting and calibrating machines.

In the wake of the booming cork industry there followed the inevitable avalanche of devices designed to extract corks. The first printed reference to a "bottlescrew" was in 1681 by one N. Grew, however the official history of the modern corkscrew is marked by the earliest patent issued for such a device - granted in 1795 in England to Reverend Samuel Henshall. (See the chapter on Corkscrews). Thanks to corkscrews, corks began to be fully inserted into the bottle neck so permitting bottles to be stored horizontally or in bins, a practice which extends the life of the cork by keeping it moist.

By the twentieth century the first industrial cork stopper manufacturing machine was in operation. The cork block was now secured by a clamp, light pressure was then applied to make an auger rotate the cork block against a sharp blade, thereby producing the totally cylindrical stoppers we know today.

The huge growth in wine production and consumption over the last three to four decades has put significant stresses on growers and producers of what has become the pre-eminent closure of choice since the 1700's. Given that the growth of the cork oak is limited to specific geographic region, as we shall see below, it seems reasonable to assume that corks, or at least good quality corks, will continue to be a sought after and expensive commodity.

| VIDEO: Types of cork and other Closures. |

Modern Cork Production

Of the estimated 12 billion cork stoppers produced each year, whole natural corks make up only a percentage. Today's cork stoppers can be found in several forms and combinations. 'Technical corks', for example, are stoppers which consist of small pieces or granules of clean, natural cork bound together with resin or a chemical binder. One or more discs of intact natural cork are stuck on the end intended to be in contact with the wine. Efficient use is made of natural raw material for their production and while they retain the expectations that wine drinkers associate with cork, they are not designed for long term cellaring. 'Sparkling wine corks' are made from a single moulding of high quality natural granulated cork. At one end there are two or three discs of fine natural cork as the discs are in contact with the liquid.

Lower grade natural cork with larger lenticels and structural imperfections, is used to make 'Colmated corks'. They are coated with a mixture of fine cork particles and natural latex to seal the surface of the cork and improve its performance as a stopper.(6)

However, of specific interest here are the creation of natural corks cut directly from harvested cork bark. Typically, these are the highest quality corks (and so the most expensive) aimed at the preservation of wine for extended maturation.

The fundamental principles involved in making natural corks have changed little over the centuries. It begins with the careful husbandry of theQuercus Suber,the botanical name for a slow growing, evergreen oak, native to southwest Europe and northwest Africa, today grown mostly in Portugal, (but also Algeria, Spain, Morocco, France, Italy and Tunisia). The tree begins life as an acorn, which may germinate naturally in the forest or under controlled nursery conditions. It requires substantial sunlight and responds well to an unusual combination of low rainfall and moderate humidity, thriving up to 1400 metres above sea level. In Portugal's southern provence of Alentejo, which supplies a significant quantity of the world's wine corks, there are more than 720 thousand hectares of sustainable cork forests and the felling of healthy cork oaks is illegal, save for essential thinning. The most remarkable quality of this astonishing tree, is of course, its rugged bark which is unique in the plant world. It is thought that the extraordinary thickness of the tree's bark, its unusual composition and incredible regenerative capacity originally evolved to protect the tree from the harsh Mediterranean conditions , where forests experience frequent droughts, brush fires and temperature fluctuations.

The most remarkable quality of this astonishing tree, is of course, its rugged bark which is unique in the plant world. It is thought that the extraordinary thickness of the tree's bark, its unusual composition and incredible regenerative capacity originally evolved to protect the tree from the harsh Mediterranean conditions , where forests experience frequent droughts, brush fires and temperature fluctuations.

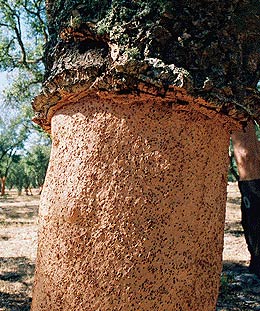

Before bark can be harvested, each tree's trunk has to reach a circumference of 70 cm at 1.5 metres from the ground, a growth period spanning approximately 25 years. The first stripping yields 'virgin bark' of a very irregular nature, too hard to be easily handled and certainly unsuitable for the preservation of wine. Nine years on, the second harvest will offer a softer, more regular structure, but still only adequate for applications such as flooring or insulation.

It is not until the third harvest, when the tree is approximately fifty years old, that the regularity, smoothness of texture and density of cells renders the bark acceptable for wine stopper usage. From then on, the cork oak will supply good quality cork for an average of 150 to 200 years, despite its bark being stripped around 16 times during its lifetime, at nine-year intervals. Testimony to this is the oldest and largest productive cork tree in the world - Portugal's famous "Whistler Tree", so called because of the numerous songbirds that occupy it. Planted in 1783, it stands more than 14 metres (45 feet) high and 4.15 metres (nearly 15 feet) in circumference. It was first harvested in 1820, and since then it has been harvested another 20 times. The 1991 harvest produced 1200 kilograms of bark - more than most trees yield in a lifetime and enough for more than 100,000 wine corks. As of June 2000, it is estimated that over one million corks will have been produced from the tree.

The bark stripping is carried out during the most active stage in the annual growth of the cork oak, from mid-May or early June to the end of August. It is an ancient and specialised task requiring experienced workers and surgical precision. Unlike most trees which die if their bark is removed, (bark helps to carry the sap that is essential to the life of the tree). The cork oak has two layers of bark."...The inner layer is alive. It is the base on which a new inner layer grows each year. As the old layers move outward and die, they serve as insulation, protecting the tree...The dead outer layer can be stripped away..., but care must be taken not to penetrate the inner living bark".(7)

To achieve this end, choosing the deepest crack in the cork bark, the harvester first makes a vertical cut. The edge of the axe is simultaneously twisted so as to separate the outer from the inner bark. The degree of difficulty of extraction can be gauged from the 'feel' of the axe. When the edge of the axe is applied to the strip, a hollow sound of tearing is heard if the cork is going to come off easily. If it is going to be difficult, the axe gives off a short, firm, dry sound. A horizontal cut defines the size of the cork plank to be removed. The plank is then prized off, by inserting the edge of the axe between the strip and the inner bark and gently twisting. Care is taken not to split the plank, as the larger the planks, the greater their commercial value. After the operation is repeated over the whole trunk, the tree is marked, using the last number of the year in which the extraction took place, so that future harvesters will know that that particular tree needs nine years before it is harvested again.(8)

|

|

| 1. Stripping panels of cork bark. | 2. Detail illustrating the thickness of the outer bark. |

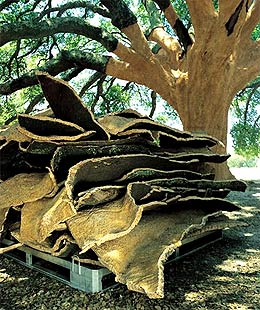

Traditionally, cork planks were stacked on bare earth or in the forest for about six months but this practice has changed due to legislation aimed at minimising the potential of microbiological contamination. Nowadays, planks are stacked on concrete in the factory yard for a minimum of six months in such a way as to maximise drainage and aeration of the pile. Throughout this seasoning period, the sap is purged and the texture stabilises until an optimal moisture content is obtained. Planks are then sorted to separate the thicker, high-quality bark suitable for wine closures from the thin bark which will be used to make cork discs. Any bark stripped from the base of the tree which is more prone to contamination than bark from higher up the tree is avoided.

|

|

| 3. Planks are packed onto steel palletes. | 4. Seasoning planks. |

A process of immersing the selected planks in clean boiling water follows. Before boiling, the cork cells appear collapsed and wrinkled, but during boiling the gas in the cork cells expands, flattening the plank from its native curved tree trunk shape. Consequently, the structure of the cork becomes more regular and its volume increases by around 20 percent. However, the primary aim of boiling is to sterilise and remove organic solids lodged in the lenticels or pores of the cork. Traditionally, planks were boiled for one hour and then re-boiled if they were destined for use as wine stoppers. This procedure was criticized as the water was not changed frequently enough, nor refreshed between batches, significantly increasing the risk of micro-biological cross-infection. Since 2000, Amorim's production plants (the world's largest cork producer), planks are boiled in closed steel tanks fitted with a special device that continuously traps and removes volatile organics such as trichloroanisole (TCA) from the washwater. The entire volume of water in the tank is filtered every 20 minutes. Only non-chlorinated, filtered water is used and it is regularly tested to ensure the absence of chemicals such as organochlorines. As a further advance from traditional methods, cork planks are now boiled in smaller, 2-tonne batches. Improved water circulation and more even temperature distribution boosts the extraction of contaminants. What's more, because of the lower humidity content of the cork (20 per cent compared with 40 per cent under the old process), the cork planks need only be left to stabilise for three days after boiling (instead of three to four weeks), considerably reducing the risk of mould growth.

After stabilisation, each plank's border is prepared and its edges trimmed before an initial manual grading. The planks are sorted into quality categories based on their thickness, porosity and appearance.

Cork punching, which gives the cork stopper its final form, is done by automatic machines or hand-controlled punching machines. An automatic machine can punch 45,000 corks a day, however the best quality bark is still punched by skilled workers, (punching approximately 20,000 corks in a day) which results in a more consistent quality, because a keen eyed worker can constantly discriminate the best sections in the cork strip from those with imperfections. Any cork wood left over from punching is sent for granulation and use in making composite corks.

At Amorin, after punching, corks are screened using highly sophisticated analytical techniques. Batches not meeting the companies high sensory standards pass through a steam treatment process, which has proved highly effective in removing volatile compounds that might taint wine. Next, using an abrasive stone, the cork heads and body are polished so that the cork will have a specific, uniform length and diameter.

The corks are then washed to further insure against microorganisms and improve the corks appearance. Traditionally this involved a chlorinated lime and oxalic acid solution followed by a residual layer of calcium oxalate to create an acidic environment in the cork. Unfortunately, when done incorrectly, it was found that this method could contribute off flavours to wine. One successful alternative has been a mild hydrogen peroxide solution, while another uses potassium metabisulfite.

The corks are then dried in industrial ovens or with sterilized air to the correct moisture content. The corks are again sorted - this time by hand - to the customer's specifications; then, if required, they are branded or printed with the identifying mark or logo of the distributor or winery. A thin film of paraffin wax and/or silicone is applied to each cork, to make it easier to insert into and extract from the wine bottle. Traceability codes are nowadays in use whereby an invisible food grade, ultra violet sensitive ink is used to ensure that each cork has its own identity. Then finally, batches of corks are packed in polyethylene with sulfur dioxide (SO2) gas, a widely-used preservative in the wine industry, and sealed in readiness for storage and shipping to cork distributors and wine producers around the world.

Cork Taint

The stringency of this rigorous quality control system, beginning from the point of harvest to the packing of the final product is a relatively recent development and was primarily a response to the real or perceived escalation of "Cork Taint". While the trained nose can detect the presence of cork taint at concentrations as low as 4-6 parts per trillion, if you have never experienced a corked wine, a badly tainted wine is one of the easier wine faults to identify and remember. If it smells like mould, damp cardboard or your sweaty shoes after a run (even faintly), then the wine (red or white) is 'corked'. Typically, the wine's native aromas are completely masked by the taint as are the fruit flavours on the palate. The frustration of cork taint is that because it occurs via contact between wine and cork, it remains undetectable until the bottle is opened. What's worse is that any wine is susceptible, regardless of price or pedigree.

The reasons behind the apparent recent increase of corked wines have been partly attributed to Portugal's 1974 political revolution that changed the management regimes and quality controls of the cork tree forests and cork factories. During this time"...unskilled or inexperienced people were managing groves of cork trees. Quality control standards were very poor by today's standards."As a result, major investment got underway in 1978, when"...Almost 2.5 million acres of cork forests had to be cleaned up, newly planted and reorganized."(9)

It should be said that there is little hard evidence to support the claim that cork taint has actually increased over the last few decades. Anecdotal alarms began ringing around 1990, when Harvey Steiman of the American Wine Review, "The Wine Spectator" estimated that 4.7% of the wines submitted to the magazine were contaminated by cork taint. More sensationally, Craig Goldwyn of The Beverage Testing Institute (1992), estimated that up to 8% of wines are tainted by the time they reach retail stores or restaurants.(10)In a pioneering study carried out during show judging in February 2004, one out of every dozen cork-sealed wine bottles at the Macquarie Bank Sydney Royal Wine Show from a sample of 2,161 wines was verified as been affected by trichloroanisole.(11) Estimates consistently come up with figures in the range of 2 - 7%, although most studies have lacked chemical verification, and to our knowledge, no definitive large scale analysis has yet been carried out. Cork industry statistics differ dramatically, with a random testing of Amorim corks in 1997 revealing that from a sample of 24,000 corks fewer than half a percentage point (0.48%) were defective.(12)

The chemical causes of cork taint were first recognised by Australian researchers in the 1980's. According to Richard Gawel from Adelaide University's Department of Horticulture, Viticulture and Oenology, six chemical compounds have been found to contributive: geosmin & 2-methylisoborneol (MIB) which offer earthy/muddy aromas; guaiacol which is smokey or medicinal, octen-3-ol and octen-3-one which smell distinctly of tinned mushrooms; and the most important of them all 2,4,6 trichloroanisole which typically has a musty, mouldy or wet hessian bag character.

"Trichloranisole or TCA as it is affectionately known"says Gawel,"is a small and chemically simple molecule. With the exception of guaiacol, these compounds are sensorially very potent. TCA can be detected in dry white wine and sparkling wines at levels around two parts per trillion (0.000000000002 grams in a litre of wine), and in red and port wines at around five parts per trillion. Such low concentrations are difficult to conceptualise but it is analogous to one teaspoon in a couple of thousand olympic sized swimming pools or one second in 32,000 years. A single gram of pure TCA could badly taint the entire volume of wine produced in Australia each vintage".(13)

While complex chemical mechanisms underlie the production of TCA, the manner in which corks become infected has been reduced to two scenarios. Firstly,"...the conversion of chlorophenols to chloroanisole by common microscopic fungi (and possibly yeasts and bacteria), in the presence of moisture. Chlorophenols", says Gawel,"have been used as pesticides and as wood preservatives and as such are common environmental pollutants. The uptake of the minutest amounts of chlorophenol by cork tree bark during any stage of its growth, or subsequent manufacture into cork will provide the potential for cork taint production".(14)

Secondly, until recently, the boiling and bleaching of cork planks sometimes took place in a strong hyperchlorite solution, which inadvertently contributed to potential taint by providing a ready source of chlorophenols for use by micro-organisms. Essentially, phenols in the cork were reacting with the chlorine to form a chemical compound called trichloropherol, which in turn was being converted to trichloranisole by moulds growing on the cork.

However it's important to remember that"TCA can also be formed in packing materials and wooden shipping container floors. It can then pass either through the air or by direct contact to previously unaffected corks." (15) adds Gawel. In fact, TCA is a major contaminant of many other foods and beverages and can be found in bottled water, beer, spirits, milk, chocolate, soft drink, packaged food products and, yes, even wine bottled with screw caps.

| VIDEO: Cork taint & one novel solution. |

And besides corks, there are other potential sources of TCA contamination in the winery - tap water, poorly maintained oak barrels, transfer hoses, filter pads, fining agents, contaminated bottling equipment, polymeric tank liners, airborne moulds, or moulds in the cellar for example. But this is no reason to assert that the majority of TCA might not be caused by corks. The random incidence of infection, with one bottle being affected while others from the same batch are not would tend to support this conclusion. Suffice to say that more independent scientific research is required before any case against corks can be confidently maintained.

Unfortunately, once in the wine, TCA is a very stable compound outliving the wine itself. No amount of subsequent breathing or cellaring will remove it. Nevertheless, several solutions have been proposed. For example, a biochemist based in Burgundy has invented a kit that promises to remove cork taint by using an ionised material known as a copolymer to absorb the cork taint molecule. The copolymer is lowered into the wine and left until the taint disappears, usually taking about one hour, depending on the degree of taint.(16)

In my own experience, there is only one way of alleviating cork taint, which should only to be used in times of total despair. Cut a thin slice of lemon. Dip the lemon slice into the glass of wine for about 10-15 seconds and both the aroma and flavour of taint will be masked. Of course the lemon slice imparts a slight lemon tang to the wine, but in desperate situations, better a lemon tang than a sweaty sock.

Duty of Care at the Bottling Line

The consumer is generally unaware of precisely what bottling practices were employed to ensure their purchase arrives in the cellar in the best possible condition. Yet it's worth while considering just how much of a wine's ability to gracefully mature, rests not just with the wine itself, but with how the cork was stored, handled and inserted. If a bottle is weeping (i.e.- leaking from the neck), for example, it may actually be the result of poor winery practices rather than due to any fault in the cork itself.

The pressure the cork exerts on the neck of a glass bottle is of course the key factor in a wine's longevity. Therefore, before bottling, the first decision must be as to the most suitable type of cork to be used, and naturally, the wine maker needs to ensure that the selected cork will also suit the inside profile / dimensions of the bottle neck in question. Wine corks grades are primarily determined by the criteria for quality of the raw material as adopted by the cork manufacturer. For the laymen, the quality of the cork can usually be determined by examining its texture and the number of pock marks to be found on the surface. A quality cork will be smooth with an even grain density along its entire length. Quality corks are also longer. Consider the length of the cork found in a first growth Bordeaux - you'll find it's about 60 mm long, as compared with the 35mm - 45mm corks used for wines destined for immediate consumption.

The plastic bags containing the corks should not to be opened until immediately before loading into machine. Before use, the cork's moisture content needs to be checked. Below the 5% level, the corks can begin to crumble and drop dust into the wine. Such corks must be discarded or returned to the supplier. Moisture levels above 8% are equally problematic in that they support mould growth which may taint the wine after bottling.

At the bottling line, corker jaws which can cause the cork to wrinkle and thus leak are nowadays avoided. A four segment sliding roller or iris jaw type cork compression system is recommended. The care and maintenance of the corking machinery is a bottlers first duty of care, where regular inspections help ensure that:

- The compression stage is a smooth action

- there is no damage to the jaw segments

- Good alignment and bottle neck seal in centering bell

- The plunger properly centered

- Daily cleaning and sanitation of the hopper, feed tube, orienter and jaws takes place

- Over compression is avoided. (Not compressing a 24mm wide cork to less than 16mm, for example)

At the point of insertion, the bottler must ensure that the neck of the bottle is dry. A bottle with wet sides will allow slippage up or down, creating the possibility of the wine leaking through this film, and further allowing the growth of micro-organisms. During insertion, the jaws of the corking machine compress an average 24mm diameter cork to 16mm to fit into the bottleneck. The cork bounces back to 18mm after insertion which means that 25% (6mm) is what is pushing against the glass to create the seal. Simultaneously, the corking machine should, "...pull a vacuum in the bottleneck after the bottle is filled with wine. Not only does this remove oxygen from the headspace but it also prevents the headspace from being pressurised when the cork is inserted. With an insufficient vacuum, the wine can leak out between the glass and cork. Too strong a vacuum creates a negative pressure which will be equalised by pulling air in alongside the cork. Thus affecting the seal and causing the wine to be compromised."(17) The headspace between the top of the wine and the bottom of the cork is critical and should be at least 15mm. Over filling of bottles is yet another cause of leaking due to the wine's expansion in warm temperatures. On a hot day or in a warm cellar, for example, for each 4oC rise in temperature, the wine will expand 1mm. This will begin to push the cork out of the bottle, most often causing the wine to leak or 'weep', impacting on the ability of the wine to achieve its full cellaring potential.

Even the speed at which bottling takes place is important. A bottling line that runs at more than 1500 bottles per hour can produce an over-rapid compression of the cork by squeezing it too fast and breaking its cell wall structure, consequently compromising the cork's integrity.

After insertion, the top of the cork and the top lip of the bottle should have a distance of plus or minus 0.5mm. If the cork is inserted too low, a number of problems are likely to occur, including leakage due to over pressure, or where the space between the top of the cork and the underside of the capsule encourages the growth of mould. Any corks not used by the corking machine are returned to plastic bags where sulphur dioxide gas is used to dose the contents.

It is recommended that a freshly bottled and stoppered wine should stand upright for at least 24 hours after bottling in order for the cork to regain its original diameter after compression. Failure to leave the cork upright can lead to leakage, as well as exposing it to fungal and bacterial spoilage. This is why the great Estates of the world do not allow their wines to be contract bottled. Rather, they choose to invest heavily in equipment which might only be used for several weeks of the year. The investment ensures that they have maximum control over the cork and subsequent wine quality.

The search for the perfect wine closure is an ongoing enterprise. This chapter is continued by two other articles:

The Search for the Perfect Closure Part 1: Synthetics

This article follows on from Vintage School 2.14 Corks & Cork Taint, and offers an insight into contemporary innovations in wine closure technology. While these new developments aim to reproduce the look and feel of natural cork using alternative materials, their significance resides in their imperviousness to micro biological contamination. Could synthetics be the perfect wine closure?

The Search for the Perfect Closure Part 2: Screw Caps

The third and final supplement to our discussion on wine closures concerns the growing phenomena of 'Screw Caps', (also referred to as Stelvin Caps). These have found great popularity amongst winemakers and continue to threaten traditional corks as the closure of preference. This article documents the recent studies and the ongoing debates surrounding the true viability of screw caps, an issue which seems destined to rage on for years to come!

* Micrographia: Or Some Physiological Descriptions of Minute Bodies Made by Magnifying Glasses by Robert Hooke (1635 - 1703) is the most influential work in the history of microscopy. Containing the discoveries which Hooke made with his newly perfected compound microscope. This graphic portrayal of a hitherto unknown micro world had an impact rivaling that of Galileo's Sidereus nuncius (1610) which had been the first publication to show drawings of the macro world beyond the earth.

** In different times and places, for one reason or another, other vegetable substances have been used instead of cork, like the South American Monbain tree (Spondas lutea) and the roots of the Liquorice plant.

1. The Structure and Mechanics of Cork L. J. Gibson, K. E. Easterling, M. F. Ashby. Proceedings of the Royal Society of London. Series A, Mathematical and Physical Sciences, Vol. 377, No. 1769 (Jun. 25, 1981), pp. 99-117

2. The Amorin Cork Company. Amorim is the world's largest producer of natural corks producing about 10 million corks per day.

3. A History of Inventions, Discoveries, and Origins. By Johann Beckmann. Translated by William Johnston. Published 1846 H.G. Bohn

4. Ibid

5. Corks - Past, Present, and Future, article from Beekam Wines & Liquors New Jersey. http://www.beekmanwine.com/prevtopindex.htm

6. Various cork type descriptions adapted from: Bottle Closures in The Wine Industry. Berence Barker, 2004. PDF format.

7. Corks - Past, Present, and Future, article from Beekam Wines & Liquors New Jersey. http://www.beekmanwine.com/prevtopindex.htm

8. APCOR Associação Portuguesa de Cortiça (Portuguese Cork Association). http://www.realcork.org/

9. Corks - Past, Present, and Future, article from Beekam Wines & Liquors New Jersey. http://www.beekmanwine.com/prevtopindex.htm

10. Cork taint found in 8 percent of wine bottles. Cyril Penn. Thursday, January 27, 2005. San Francisco Chronicle.

11. Ibid

12. The Amorin Cork Company. See http://www.corkfacts.com. Amorim is the world's largest producer of natural corks producing about 10 million corks per day.

13. Cork Taint in Wine. Richard Gawel. Adelaide University's Department of Horticulture, Viticulture and Oenology. Winestate Magazine, July / August 1998.

14. Ibid

15. Ibid

16. Burgundy boffin invents remedy for cork taint. By Oliver Styles. Decanter Magazine, May 11, 2005

17. Bottle Closures in The Wine Industry. Berence Barker, 2004. PDF format.

Other general information on cork manufacture / bottling adapted from The Amorin Cork Company &

The Natural Cork Quality Council (www.corkqc.com/recommendedqcpractices) regarding good practices to be undertaken as a responsibility of the winery, adapted from: Bottle Closures in The Wine Industry. Berenice Barker, 2004. PDF format.