2.13 Barrel Maturation & Wine Flavour

|

| Important elements of oak barrel production for wine maturation include species of oak, method of wood harvest, stave seasoning, barrel construction and size. |

It is a seldom celebrated fact that the barrel, like the wheel, is one of the inventions that has transformed civilization. Almost universal until fairly recent times, not merely because they were stronger than the storage devices that had preceded them, but because they were ingenious in form as well as function.

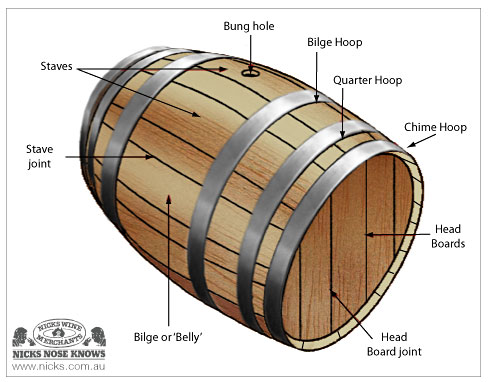

A barrel of the kind seen in wineries today could be thought of as two sets of perpendicular arches. Each stave abuts two neighbours, collectively forming a remarkably sturdy construction - any impact is absorbed by every other element in the barrel.* Its shape also makes it a laboursaving device. It can be handled by one person even when full by rolling it on its edge when standing upright, and when on its side, thanks to the bowing out of the staves in the middle, only a small part of it touches the ground so that a light push will start it rolling in a straight line.

Wherever the 'proto-barrel' first surfaced**, it probably began as a hollowed stump sealed with hides at either end which would have inevitably leaked and imparted bacteria to the contents. While the ancient historian Herodotus refers to palm wood casks being used to carry Armenian wine to Babylon in Mesopotamia, the Roman writer Pliny thought that the first barrel makers lived at the foot of the Alps in Piedmont, Italy. It's now accepted that it was the Iron Age communities of Northern Europe, notably the Celts, who were the first to perfect the water-tight barrel that led to the large scale transport of goods. ***(1) Being as skilled with iron as they were with timber, Celtic shipwrights would have realised that a boat was essentially a water-tight half barrel. Extrapolating from that, they built a 360 degree version with iron hoops to hold it together. In fact, the word 'Barrel' literally means 'secured by bars' and the Celtic words 'quer' (fine) and 'cuez'(tree) give us the word' Quercus'still used for the oak species today.

It's hard today to conceive how ubiquitous the barrel must have been in the eighteenth and nineteenth centuries. It was the essential cargo container for over two centuries, filling the holds of clipper ships, stacked on buckboards en route to remote settlements, and filling boxcars of expanding railroad networks. Untold thousands of barrels were used to transport almost every kind of commodity: milled flour, gunpowder, molasses, cotton, sugar, fruit, soap, coffee, salt, whisky, wine, tobacco, shoes, paints, pickles, chains, powdered chemicals, cement, wire, nails and even cash money. Beef and pork were shipped in brine in wooden barrels. The sheer variety of goods necessitated two kinds of barrel makers: At the top of the profession were Wet Coopers, who made water-tight barrels for storing liquids using oak, chestnut or beech, while Dry Coopers made barrels of pine or fir for shipping dry merchandise. When the barrels were rolled into shops, and the upper hoops were popped off and the heads removed, they instantly morphed from container to display, much like corrugated cardboard boxes reveal their contents in warehouse-style stores today.

It's hard today to conceive how ubiquitous the barrel must have been in the eighteenth and nineteenth centuries. It was the essential cargo container for over two centuries, filling the holds of clipper ships, stacked on buckboards en route to remote settlements, and filling boxcars of expanding railroad networks. Untold thousands of barrels were used to transport almost every kind of commodity: milled flour, gunpowder, molasses, cotton, sugar, fruit, soap, coffee, salt, whisky, wine, tobacco, shoes, paints, pickles, chains, powdered chemicals, cement, wire, nails and even cash money. Beef and pork were shipped in brine in wooden barrels. The sheer variety of goods necessitated two kinds of barrel makers: At the top of the profession were Wet Coopers, who made water-tight barrels for storing liquids using oak, chestnut or beech, while Dry Coopers made barrels of pine or fir for shipping dry merchandise. When the barrels were rolled into shops, and the upper hoops were popped off and the heads removed, they instantly morphed from container to display, much like corrugated cardboard boxes reveal their contents in warehouse-style stores today.

One would have expected dramatic advances in health standards and transport methods, not to mention tin cans, steel drums, corrugated cardboard boxes, inexpensive glass jars, and durable plastic containers to have all but destroyed the cooperage industry. It's certainly true that the barrel has been displaced, but it has been assured of an ongoing role, thanks in part to historical coincidence and a curious fact: Certain beverages are uniquely enhanced by exposure to oak. So much so that the oak barrel is generally considered the most important element of many wines and spirits next to the source of the raw liquid itself. Concrete tanks, large glass jugs (demijohns) or stainless steel vats can suffice, but overwhelmingly modern wine and spirit of any high quality is matured in oak barrels, forming the basis of the entire modern cooperage industry.(2)

Oak Barrels & Wine

It's a relatively recent recognition that the contribution of oak flavour is highly desirable in certain wine styles such as Shiraz and Cabernet Sauvignon to the extent that some producers now consider the barrel to be the most important wine making tool. There are exceptions - delicate, lighter wines like Riesling, Chenin Blanc and most Sauvignon Blancs as well as certain red varieties such as Gamay (Beaujolais) rarely receive oak treatment. They are styles that reveal their virtues when youthful and fresh.

Originally wine was stored in barrels purely because they were robust and manageable storage vessels.

Coopers experimented with a variety of woods. In Europe, chestnut (traditional in central Italy), fir, spruce, pine, larch, ash and mulberry were used. In New World wine regions, a variety of American straight grained timbers were tried including chestnut oak, sweet gum, sugar maple, yellow birch, white ash, Douglas fir, black cherry, sycamore, redwood, spruce, bold cypress, elm and basswood. Trial and error gradually disqualified all these timbers. Douglas fir and pine spruce contributed a resinous aroma and flavour, ideal perhaps for Retsina, but hardly suitable for premium table wine. Extended maturation in Californian redwood often resulted in a disagreeable off flavour. Meanwhile, in early Australia, native trees such as the eucalypt, acacia, karri, jarrah, stringy bark and she-oak proved to be suited for the construction of very large vats and barrels but did little to enhance wine. The acacia tree actually imparted a yellow pigment. Only oak was found to possess the rare combination of qualities needed for wine barrels: strong, resilient yet bendable, it imparts no objectionable flavours or colours and forms a liquid tight container with minimal shrinkage (wet to dry). Not surprisingly, it's used almost exclusively to this day, with the exception of chestnut , which is more porous and needs a paraffin coating to prevent excessive evaporation.

Of the 200 species of the oak genus, only three species are preferred for use in winemaking.

Quercus Robur and Quercus Sessilis are from the European oak family, and to all intents and purposes very similar species, their only perceived difference appearing to be the construction of their acorns and how they are attached to the tree. These species have a distribution across Europe from the British Isles, beyond Warsaw in Poland, towards Odessa in Russia, Scandinavia, the Balkans, to Italy and Northern Spain. They grow side by side and easily hybridise. The most important forests are found in France where they occupy approximately 4.5 million hectares. There, differences in regions or appellations are generally considered more significant than the raw material, and in the case of oak this means that forest terroir rather than the species of oak are emphasised and marketed. The principal regions which supply the wood for making wine barrels are Limousin, Allier, Troncais, Bourgogne, Nevers and Vosges.(See below for profiles of oak from each region).There is in fact an overlap of oak species in most of these forests and other species of lesser significance can be found including:Q. afares, Q. macranthera, Q. longipes, Q. imeretina, Q. iberica, Q. pedunculiflora, Q. lamugnosa, Q. farnetto, and Q. mirbeckii. It should be added that there are other areas in France that supply oak wood and oak forest regions are broadly defined.

The second large cooperage industry is in America, where the predominant oak isQuercus alba, estimated to account for 45% of the standing white oak east of the Rocky Mountains. It grows in the widest area from Southern Canada nearly to the Gulf of Mexico and from the Atlantic to Iowa, and south up to Texas. However, several other species are also found and may be used for making barrels. + Oak wood obtained from Missouri, Kentucky, and from the northern part of the U.S. for example, is more likely to includeQ. bicolor and Q. macrocarpa; while the staves obtained from Arkansas and the South are likely to have come fromQ. prinus and Q. Iyrata.++ Because staves made from Q. alba and other species are difficult to distinguish, it is satisfactory to assume that American oak barrels are made largely from Q. alba and to some extent, other species. Since the influence of American oak barrels on the sensory attributes of wine is fairly consistent, it is also safe to assume that the chemical and physical properties of oak wood from these other species is similar to Q. alba.

Profiles of the Main French Oak Growing Regions Profiles of the Main French Oak Growing RegionsLimousin [li-moo-sahn] oak comes from the old French province of that name in the southwest of France, near the city of Limoges not far from Cognac. It is the only French forest that is predominantly Quercus Robur. The toughness and coarse (open) grain of the wood is a result of poor growing conditions, porous and sandy soil lacking in some important nutrients and minerals, which tend to restrict vertical growth in favour of a shorter, larger diameter tree trunk with irregular grain. Limousin oak is at one end of the scale in terms of looseness of grain; the release of flavours is too aggressive and more oak tannin is extracted than from other forests. Consequently, Limousin is used almost exclusively for the maturation of Cognac. Allier [ah-leay] oak comes from the Departement in south-central France named after the Allier River. Predominantly Quercus Petrae, the highest percentage of any French forest. The soil here is thick clay, siliceous and not very fertile, and so the growth of the tree is very slow resulting in tall, straight trunks. The grain of the wood is fine, compact and slightly porous resulting in sweet tannin extraction and pleasant aromatics. Troncais [tron-say] oak comes from a specific forest within the Allier Departement and is the best known of a number of forests deliberately planted in the late 17th century under Louis XIV to provide oak for the French navy. Regarded as the most beautiful forest of France. Quercus Petrae dominates here. The excellent growing conditions make for very rapid vertical growth and minimal lateral expansion, resulting in an extremely tight grain. Subtle oak flavours make Troncais well suited for prolonged barrel aging. The limited production capacity of this sub-forest means that the oak is prized and in great demand. Nevers [ne-vere] oak comes from the many forests of the Nievre Departement in the centre of France. The region is gently rolling and the soils are rich and moist resulting in trees that grow tall and straight. The oak from Nevers is usually medium grained compared to that of Allier. The result is a bigger tannin extraction than that of tighter grain wood and requires longer aging time to fully integrate with the wine. Vosges [voej] oak comes from the low mountain region of that name in the northeast corner of France near the Alsatian border with Germany. The trees are tall with narrow trunks and the timber is medium-tight grained. This oak only became commercially available in the late 1970s and the forest was the most damaged by the hurricane of 1997 and consequently there is less wood of this origin compared to the past. The character of Vosges oak varies according to the altitude of the stand and compared to wood from Nevers and Allier, it tends to be wider-grained though not as much as Limousin or Bourgogne. |

Eastern European Oak Oak from the Baltic states, Serbia and particularly Hungary was very highly prized by barrel makers in the nineteenth and early twentieth centuries. The oak species throughout a crescent-shaped area, ranging from northern Portugal up through France to the Baltic states and down through Hungary and Romania, belong to the Quercus petraea and Quercus robur families. Yet a good deal of diversity in flavour and structure is evident depending on the precise microclimate, soil structure and density in which the trees grow. The taste of French oak, now considered integral to the flavour of red Bordeaux, was not appreciated in Bordeaux's traditional market in the early and mid-nineteenth century. Winemakers preferred the softer, smoother texture Hungarian oak offered their wines, perhaps because less charring of the barrels was practiced. The substitution of French oak for Baltic and Hungarian oak was prompted by political difficulties, including the Napoleonic wars. It is only in the last twenty years that the Hungarian Oak trade has been re-established with French coopers. In the Czech Republic, barrel production was primarily for the beer industry. The wine region of southern Moravia did require some cooperage for wine, but until recently, barrels were viewed only as storage vessels. Oak flavour in wine was considered undesirable. The development of export markets has encouraged more wine barrel production, and in depth studies of Bohemian and Moravian oak are now underway. In Russia, the southern region of Adyghe, near the Black Sea, has been identified as having a large source of Q. sessilis. The less expensive cost of wood from this area has stimulated significant interest. - notes on European oak sourced from www.bouchardcooperages.com |

Making a Wine Barrel

It is testimony to the ancient genius of the Celts that despite modern research, machinery and wood selection techniques, the fundamentals of the barrel making process have changed very little over the centuries. There are construction variations according to the type of oak being used and between country, region and cooper, but to achieve the highest standards of quality much of the work must still be done by a skilled cooper with an apprenticeship even today of five to seven years' duration.(It has been mentioned that the purpose of long apprenticeships was partly to keep down the numbers entering the craft, and thereby keep wages high. Apprenticeship periods now vary).

|

A barrel begins its life from trees that are around 100 to 150 years old. For coopering to be viable, large trees with straight defect-free grain for the length of the staves are required. Sections of straight trunk about 1.5 metres in diameter are usually harvested in the winter or autumn when the sap is least active. 2-4 barrels might be expected from each trunk.

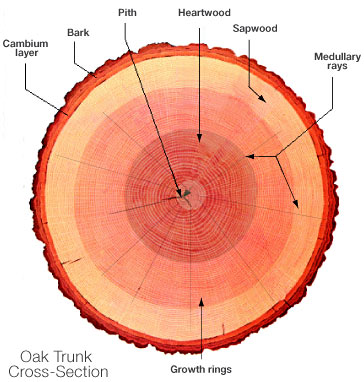

There are two distinct methods for dividing the trunks into barrel staves, dictated by the structural features that make European oak(Q.Robur, Q.Sessilus) and American oak(Q.Alba etc.) so suitable for wine barrels. These are their 'medullary rays' and 'tyloses'. For the non-botanically minded, medullary rays consist of elongated cells or 'ribbons' extending vertically through the tree across and perpendicular to the growth rings forming a spoke-like arrangement outward from the core. The rays are diffusion channels - or 'tubes' for the transmission of water, sap and nutrients. In conifers the rays are small, one cell wide and are called uniseriate. In oak the rays are two or more cells wide and are called multiseriate. These wider rays help make for strong and resilient wood.

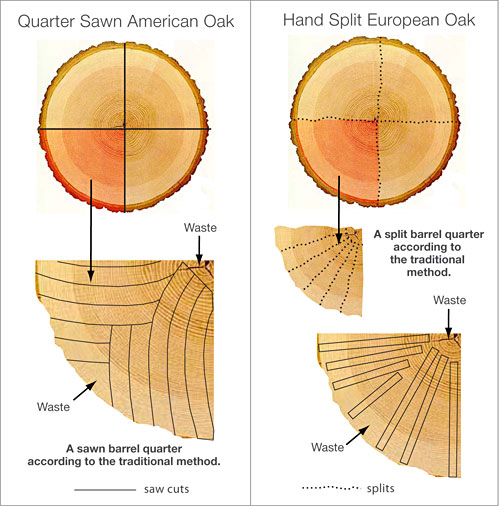

The key difference between European oak and American oak is in the structure of these medullary rays. American oak possesses an abundance of natural cellular growths called 'tyloses' that seal up the heartwood (the dense inner part of a tree trunk that yields the hardest timber). At the intersections with the medullary rays in the growth rings, these rays concentrate tyloses, creating dams. Tylose blockages permit American oak to be sawn to form staves that do not leak. The procedure is known as "Quarter sawing" and involves cutting a round log in quarters. Following cuts are then made in directions parallel to the two primary cuts, until the pieces are too small to be of use (see illustration below). Quarter sawing is relatively efficient recovering about 50 percent from each suitable log for stave use.(3)

European oak, on the other hand, does not seal its heartwood with tyloses. Consequently it is never sawn, but must be hand-split along the lines of medullary rays. Splitting makes certain the tubes or pores extend the length of the barrel stave. While yield loss from splitting is tremendous, with only about 20 percent of a log being usable, if sawn, a tube opening in the interior and leading to the exterior of a barrel will invariably leak.

The up shot is that for either type of oak when appropriately cut, a molecule of water will have to pass through five or more large medullary rays in order to escape through the side of the barrel. Thus these rays provide a formidable barrier to the diffusion of liquid and make oak wood relatively impermeable.(4)

Above: Basic illustration of the two main techniques of stave production. There are other variations.

After dividing and planing, the stave wood is stored outside in tiers to dry. Seasoned by the weather for 18 - 36 months or longer until the level of humidity in the wood is about 15 per cent ensures the end construction will not further dry and contract causing leaks. Open air-drying (as compared to the more rapid kiln drying) either in stacks in the forest or in the cooper's yard, is preferred as it dries the wood more evenly, retains aromatic qualities and leaches more tannin from the wood (resulting in a 'softer' beverage). Some high quality wine producers in Europe will buy in staves and weather it themselves, in order to ensure the process is carried out just to their liking. (Yalumba is one of the few wineries in Australia that do this - in fact they have their own coopers to make the barrels for their Octavius wine).

For the reason that there can be significant differences from tree to tree, a typical barrel will be made from about thirty staves selected from different trees of different ages growing in different locations and at different growth rates. Such a variety of staves in a barrel help to ensure more uniform quality and performance.

| VIDEO: Toasting levels. |

The skill of the cooper lies in forming the barrel with each stave being precisely cut, beveled, assembled in form, then bent and toasted. Staves are first trimmed into oblong lengths with a taper at each end (a double taper), and the inside of each stave 'scalloped' to make for easier bending - the whole process is known as 'dressing'. The finished staves are then assembled on a jointer known as a'colombe' and given their final shape - wider in the middle and narrowed at the ends. Unlike most wood, oak becomes semi-plastic when subjected to heat in the presence of moisture, so the bending of staves is usually accomplished by steaming which also modifies the wood's physical and chemical composition. Some coopers use a winch to gradually arch the staves and tighten them to obtain the shape of the barrel body which is then held trussed in place with temporary hoops. The barrel is assembled over a metal fire-pot also known as a 'chaufferette' usually fuelled by stave off cuts. Depending upon the heat of the flame, how long it is applied, the moisture content of the stave and more-so, the cooper's own judgment, the degree of toasting will vary and dramatically influence wine flavours. Light, medium or heavy are standard grades of toasting specified by winemakers today.(5)

Once the body is formed, the heads or barrel ends are shaped (being usually circular or oval), comprising five or six straight staves pinned together with dowel or stainless steel gudgeons (headless nails). The rim of the head is cut to fit into a groove or 'croze' cut in the inside ends of the staves. The head is then inserted by loosening the hoops and fitting it into the croze.

A rigorous test of impermeability follows by pouring a small amount of hot water under pressure into the barrel. This procedure makes it possible to immediately detect even minute traces of moisture caused by unusually porous areas or manufacturing defect. The outside is planed smooth for splinter free handling and the temporary hoops are removed and replaced by permanent hoops usually made of metal or sometimes chestnut.

|

|

|

| 1. Oak tree identified for harvest. | 2. Oak staves seasoning outside. |

3. 'Dressed' & bent staves, ready for assembly. |

Throughout the barrel's harvest and construction, the chemical composition of the oak wood is changing. Coopers have learnt that levels of certain compounds can actually be controlled by seasoning regimes, bending techniques, toasting times and temperatures. Cellulose is the major constituent making up about half the dry weight of the wood. It contributes to the strength but undergoes little chemical alteration during the processing. Hemicellulose makes up to 20-25% of the wood volume and the open air seasoning of the staves initiates the breakdown of the cellulose into simple sugars. As oak climbs through 150oC (300 F) during toasting, more simple sugars form and caramelized sugars and sweet-associated aromas then develop. Toasty characters arise as the oak passes 215oC (420 F). Another compound called Lignin constitutes approximately 25-35% and can be degraded by heat, ultra violet light, hydrolysis, microbial action and other effects of seasoning. Toasting also accelerates its degradation. Approximately 1% of American oak and around 8% of French oak mass also consists of tannins, though of a different kind from those found in grapes. Heartwood close to the sapwood is richer in tannin than the heartwood close to the pith. Higher tannin levels are found in the base of the tree than near the crown. The tannin content increases as the tree gets older. Oak tannins are often referred to as hydrolysable because they are unstable at wine pH and breakdown yielding gallic and mostly ellagic acid. Ellagitannins are astringent and precipitate proteins. They play a significant role in wine maturation and their levels can be influenced at every phase of the barrel production process.

|

|

|

| 4. Assembling the barrel. | 5. Toasting the insides of the barrel. | 6. The finished product, sanded smooth and labeled with the cooper's brand. |

Amidst all of these variables, it's not surprising that the reputation of any cooperage is built upon their ability to make a uniform product year in year out. To this end, while machinery will probably never completely replace the cooper, science and technology have mechanised some of the process and helped to achieve more consistent results. State of the art cooperages nowadays employ digital "Barrel Profiling" systems, temperature sensors, computer networks and touch screen monitors making possible precise toast levels, definable flavour profiles with guaranteed repeatability and predictability.(6) Homogenisation is the new philosophy underpinning barrel production and it is helping winemakers achieve more consistent results with every vintage.

The Maturation Process

Once filled with wine the barrel is stoppered to minimise oxidation. Previously in Europe, all barrels were plugged with a burlap cloth wrapped underneath the wooden bung. In the New World, a wooden bung with paraffin or tar was used. (The disadvantages of these two methods for sealing the bunghole are the occurrence of leaks, cracked wooden bungs, and over-oxidation). Nowadays a silicone bung is preferred. As the maturation process begins, substances are gradually extracted from barrels which can influence the bouquet, taste and/or mouthfeel of both red and white wines. The range of flavour categories oak can contribute to wine can be varied. Here are some that are commonly agreed upon:

HERBACEOUS: Weedy, Dill, Mown Hay, Menthol, Grass, Tobacco.

WOODY: Planky, Cedar, Sawdust, Pencil Shavings, Sappy, Green, Pine, Tar, Resin.

ASTRINGENT: Harsh, Chewy, Bitter, Angular, Tannic, Drying.

SPICY: Clove, Cinnamon, Coconut, Vanilla.

Additional flavours which can result from toasting the barrel fall into seven categories:

SWEET: Brown sugar, Bourbon, Cotton Candy, Chocolate, Maple Syrup, Butterscotch, Hot fudge, Caramel, Molasses, Honey, Toffee, Soy.

CREAMY: Vanilla, Cream soda, Marshmallow, Lactic, Butter.

YEASTY: Popcorn, Baked Bread, Bread stick, Cookie dough.

NUTTY: Hazelnut, Walnut, Almond, Peanut butter, Coconut.

ROASTED: Cedar, Graham cracker, Toasted bread, Coffee, Mocha, Cereal.

SMOKY: Barbecue, Grilled Meat, Bacon, Sweet smoke, Burnt sugar.

SPICY: Nutmeg, Cinnamon, Clove, Licorice, Anise. (7)

To the layman these might appear to be a rather fanciful use of descriptors, but as with other wine related vocabulary, these words have in fact a basis in science (see chapter 3.5 Contemporary Approaches to Wine Evaluation). Oak compounds responsible for many of these sensory characteristics have been identified amongst the following:

Guaiacol and 4-methylguaiacol have smoky aromas and are indicators of the relative toast levels of barrels. These compounds are formed almost exclusively by the degradation of lignin during the toasting process. The degree of toasting is, therefore, an important factor. The use of wood smoke is another source of these compounds and the burning of oak offcuts during the coopering process may also enhance this character.

Vanillin is the main flavour compound in natural vanilla. It can be extracted in significant quantity from unheated oak wood and in even higher amounts from strongly heated wood. It is generally considered to be an important contributor to the character of barrel-aged wines. Vanillin can be transformed by yeast metabolism during fermentation and vanillin concentration can be reduced considerably if primary fermentation is carried out in the barrel. In general, vanillin is formed in increasing amounts at increased toasting levels and levels are not influenced by origin, or seasoning period. The more dominant vanillin aromas and flavours that American oak imparts have become trademarks of Shiraz wines from South Australia.

4-Ethylphenol and 4-ethylguaiacol are products of Brettanomyces yeast (aka 'brett') and are found in virtually all Australian barrel-aged red wines. 4-ethylphenol is responsible for the 'sweaty saddle/band-aid' aroma of red wines when present in high concentration, and is generally regarded as detrimental to wine quality. Analysis of wine in barrels will determine whether this compound has been formed in high concentration during maturation and may indicate the need for changes in how the wine is subsequently handled.

Furfural and 5-methylfurfural are generated by the breakdown of carbohydrates, in particular cellulose and hemicellulose, during the toasting process. The concentration of these compounds can decrease during heavy toasting levels. These compounds have a sweet, caramel or butterscotch aroma. (8)

Monoterpenes, sesquiterpenes and many norisoprenoies have been found in oak extracts of both American and French oak. Norisoprenoids are important to the flavour of tobacco, tea and some fruits. Not surprisingly, they are believed to produce the aroma and flavour of oriental tobacco in oak matured wines.

Eugenol is the main aroma compound found in cloves. Present in raw oak, eugenol is reported to increase during open-air wood seasoning. Eugenol and isoeugenol possess a very similar spicy, clove aroma. Release into wine is reported to increase according to the level of toasting.

Wood lignin degradation at very high temperatures results in formation of a wide range of volatile phenols including guaiacol and 4-methylguaiacol. These compounds have smoky aromas, and are markers of the smoky character imparted by heavily toasted oak. Guaiacol has a char aroma, while 4-methylguaiacol has both char and spicy characters. (9)

The sensory impact of oak tannins is widely assumed to have an impact on astringency and mouth feel of a wine.

There are other oak constituents extracted during a wine's maturation - many at levels below our sensory threshold, however, they may have indirect effects. Not all of them are known. Future research will no doubt continue to identify and account for their sensory impact. (10)

| VIDEO: American Oak / Oak Selection |

Winemaking Approaches to Oak Selection

In order to make an intelligent choice between new or old barrels, American versus European oak (or a combination of any or both), winemakers must be aware of the differences. There are probably as many different approaches to this subject as there are winemakers, however, several principles are universally agreed upon. Firstly, 100% new oak (i.e. barrels that have never held wine) can often overpower the fruit in a wine. For this reason, winemakers will often employ barrels from a previous vintage, which in turn means that the previous vintage will have to come out of wood and be bottled to make way for the new wine. Secondly, winemakers have recognised that oak matured wines (especially those with a percentage of newer oak) live longer in the bottle than wines without oak maturation. The chemical reactions between barrel and beverage which extend a wine's longevity are not completely understood. We posed the question to several winemakers."There's a quite valid reason for it"explained Andrew Sutherland Smith of Warrabilla Wines."Oak is relatively high in natural tannins. These are the natural preservatives of nature (being astringent tasting or anti-microbial)". It follows that wine matured in new oak barrels as opposed to previously filled barrels will extract significantly more oak character, including more tannins. McLaren Vale winemaker, Corrina Rayment agrees."The more tannin there is, the more the colour can be stablised as aging happens"she says, associating colour as a signifier of a wine's aging potential (See 3.3 Wine Colour & the Limits to Visual Assessments)."There are tiny bits of oxygen that permeate into the wine during barrel maturation, and these result in chemical reactions that polymerise (make longer) the tannin structures. The longer the tannin structure, the more stable the colour is and the softer the wine is. So there is some chemical background to it. However, a lot of the reason why wine aged in barrels seem to age better is just the fact that better fruit is chosen to go into barrels. That fruit is stronger in the first place & therefore ages better anyway than a wine that wasn't chosen to go into oak. Barrels are expensive, so only the best goes into them!"(13)

Which species of oak is ideally suited for the maturation of a given wine is the subject of ongoing debate amongst winemakers. American oak has a higher concentration of odorous compounds such as vanillan and oak lactone (trans- B-methyl-y-octalactone) than European oak giving it a more aggressive mouthfeel and more vanillan character. On the other hand, the tight-grained European oak contains more tannins, one and one-half times more extractable solids and twice the amount of extractable phenols of American oak, delivering a more subtle flavour. (Coopers in California have been successful in reducing the differences between the two oaks by employing production techniques traditionally used by French coopers.) In a tasting seminar organised by 'The Institute of Masters of Wine' in June 2005 on the use of oak in winemaking, the conclusions drawn regarding the differences of oak from various French forests such as Troncais, Vosges & Centre were so subtle as to be "inconsequential" . The general consensus was that "..Intense smoke and clove proved most common in French oak while vanillin is more pronounced in American oak". (11)

Corrina Rayment adds,"...at the end of the day you go with the oak that you think best suits your fruit & the style of wine that you want to make...along with the price point of the wine." (13) With French oak barrels at around AU$1000 - twice as expensive as American oak - price is often the ultimate determining factor.(12) Barrel maturation also adds the costs of labour, storage time and maintenance materials to a bottle of wine for which the end consumer pays.

|

| Looking into a stainless steel tank of Chardonnay and floating oak chips. |

Oak Chips and Other Tricks

"Good oak should give a richness, nose characters, and mouth feel "states winemaker, Andrew Sutherland Smith."Our barrels are predominately puncheons (450 litres) which allows the wine to age slower than the hogsheads the rest of the industry seems to standardize on. You need to be physically fit and have a bit of weight behind you to work with puncheons, they're just too heavy and awkward but it suits our style. All our oak is A.P. John - the Rolls Royce of Aussie cooperages. It's what the best Barossa wineries use, which is part of the big generous style they make. Some nice cream caramel tones come from these barrels; subtle yet firm and persistent... These characteristics are probably also available from the way, way cheaper oak barrel substitutes... the chips powder and liquids. So why not use them?"(14)

One obvious method for reducing the cost incurred by oak aging is to purchase second-hand barrels. As many top wineries use only new and one-year-old oak, there is a good supply of two-year-old barrels, which will still be in good condition. However, to meet market demands without going broke on oak barrels, many vintners resort to alternative oak products that impart toasty oak-like overtones at minimal price; though techniques vary depending on the goals of the winemaker, alternatives include fermenting and aging wines in contact with oak chips or solid staves, oak chains, chips or extracts. These practices are legal in many New World wine regions, yet most producers hesitate to acknowledge them as consumers tend to perceive oak barrels to be synonymous with high quality wine.(15)The perception is usually correct - if a bottle of wine retails for less than $15 it's highly unlikely that it has ever spent time in a barrel.

The most common oak alternatives are oak chips. These can be added at various stages of the winemaking process, either thrown straight into the ferment or dipped into the wine tank via big bags to seep in flavour like tea bags do. Like barrels, oak chips come in a variety of different types, varying in their forest of origin, in their size, the amount they are toasted, and whether they have been water pre-soaked. Toasting chips gives them a smoky, bacon and caramel character. Due to their greater surface area, smaller chips give more character per unit weight added, and water pre-soaked chips are lower in astringent tannins."Time is the big factor,"says winemaker Simon Adams, based in Australia's Barossa Valley."If you need rapid turnover, the quickest extraction comes from the adjunct with the most surface area." Fermentation with oak chips can deliver in a matter of weeks an intensity of oak character it would take one to two years to achieve in oak barrels.(16)

The use of oak powder is less common than chipping, although they are a very practical alternative if oak character is to be introduced during fermentation (a timing which many winemakers prefer as they feel that better oak integration is achieved if the character is introduced early).

Wines can also gain oak character by inserting oak planks or staves into a tank (the highly successful 'Yellowtail Chardonnay' that won a gold medal at the Royal Melbourne Show in 2001 was made solely with oak staves). Two variations of the method exist. Either longer planks are held vertically or shorter staves are stacked in a log cabin fashion at the bottom of the tank. These systems are cost effective and yield good results in terms of quality as the wine undergoes temperature controlled fermentation in tank in the presence of oak, achieving acceptable oak and fruit integration. The method is also practical as once sufficient oak character has been imparted, the planks can be lifted out, dried and used again.

To return to the initial question, given the diversity of inexpensive oak substitutes, why persist with barrels?

Most seasoned wine tasters seem to agree that wines matured in oak barrels are usually better than those which have had oak character imparted to them using alternatives. There are several reasons why. Firstly, it's much harder to achieve seamless fruit and oak integration using alternative methods of oaking than it is with barrels. Chipping and powdering can also produce a brown paper bag like flavour due to extraction of the celluloses from the wood, whilst tank staves may produce more obvious bacon and smoky aromas. Secondly, the answer lies in not so much in the chemical nature of the oak itself but in the fact that a barrel is unique in that it allows controlled amounts of oxygen in and out of the wine over a long period of time.

Slow Oxidisation

This brings us to the second important aspect of the mechanics of barrel maturation.

"Part of what is happening in a barrel is the slow controlled pickup of oxygen."explains Andrew Sutherland Smith. "This reacts with the tannins present (and not just the oak tannins!) to stabilize the red colour and soften the tannins...The wines tend to breathe...Smaller barrels give oak characters, and develop faster than bigger ones due to their higher surface area to volume ratio".Consequently, as Veteran Penfold's winemaker Peter Gago states, "Oak vessel volume and dimensions are a important winemaking variables".(17) The table below shows the relationship of surface area to volume expressed in square centimetres per litre capacity of the barrel.

| Volume in litres | Barrel surface area in cm2 / litre |

| 20 | 195 |

| 200 | 90 |

| 2000 | 42 |

| 10,000 | 24 |

| 100,000 | 11 |

Note that a ten times increase in barrel volume reduces the surface to volume ratio by nearly half.

Therefore, supposing a winemaker has a red wine that requires 3 years of barrel aging in a new 200 litre (53 gal) barrel, he or she has the option of cutting down the aging time in half by using ten 20 litre capacity barrels. This means storing and monitoring ten barrels instead of one. Conversely, it could be decided to use a 2000 litrebarrel (10 times larger), requiring twice the amount of time (6 years) to get similar aging effects, however, long storage can be expensive. Over time, barrels of around 200-300 litres have become the standard, being a compromise between needing too many barrels on one hand and requiring unacceptably long aging time on the other. Common sizes of barrels currently used are listed below:

| Barrel (United states, typical bourbon whisky barrel) | 190 litres |

| Barrique (Bordelaise, Bordeaux) The most widely used today. | 225 litres |

| Barrique (Bourgogne, Burgundy) | 228 litres |

| Hogshead | 300 litres |

| Botte (Italy) | 400 litres |

| Butt (Sherry) | 490 litres |

| Puncheon | 475 litres |

| Fuder (Germany) | 1000 litres |

Peter Gago continues,"Oak contributes flavours, contributes tannin, but it also allows a small amount of oxygen transmission. This small amount of oxygen helps soften tannins and diminish off-flavours. The porosity of oak also permits the evaporation of water form the wine and this concentrates and harmonises the wine's flavours".

The process works like this: The oak wood in a wine barrel contains a fine, porous micro-structure which as a tree, helped supply the nutrients that allowed it to grow. These capillaries, like blotting paper, suck the liquid components of wine (water and ethanol primarily) through the barrel wall, out to the barrel surface where they evaporate, typically at a rate of 300-600 ml/week in a barrique, depending on the relative humidity in the barrel store. The power of this capillary action is enough to force a vacuum within a stoppered, tight barrel. An incorrect, but typical reference in a respected winemaking text states:"The existence of vacuum in the barrel is proof that air is not able to diffuse into a wet full barrel, which means that oxidation of the wine through the barrel walls is not significant ".In fact, the porosity of Oak runs "both ways", allowing outside air (~20% Oxygen, 80% Nitrogen) to be sucked into the barrel by increasing vacuum until equilibrium is reached between the rate of evaporative loss and the rate of incoming air.

Wine maturation, i.e. softening of tannins, intensification of colour, added stability and complexity, relies on steady, gradual oxygen permeation into an "oxygen-starved" environment. Minimal oxygen pick up can also occur during wine processing operations such as topping up, pumping, filtering and racking, however, It is the steady, gradual permeation of oxygen through the two way "Oak Membrane" that primarily sustains the slow-oxidation, polymerisation and condensation reactions which soften and mature wine after initial oxygen from barrel filling is used up.(18)

| VIDEO: Wine Barrel Maintenance. |

Alternative oaking methods in conjunction with micro-oxygenation, the process of adding small, accurately measured amounts of oxygen to a wine over a period of time to replicate the environment of new oak barrels come closer to achieving the evolution and integration of flavours from oak.(19)Despite these developments, the vast majority of winemakers agree that (cost aside) new barrels remain the tool of choice for high-end wines.

Unfortunately for winemakers and consumers, the average wine barrel has a useful life of only five to seven years. After that time, the oak has little or no beneficial flavour components left to impart to the wine and so becomes essentially a neutral container. Even gas-permeability is lost as the staves become clogged with bitartrates and other wine solids, so that without forced adding of oxygen via micro-oxygenation, wine cannot be matured. Barrels can be restored by shaving away several layers from the inside of the staves to expose new wood followed by re-toasting, or adding inner-stave oak slats, oak chains, chips or extracts. This can extend the life of a barrel up to ten years, however, the results are not the same as with new wood. For that reason, after the initial life cycle of the barrel, most wineries purge their old stock. Often these barrels are cut in half and sold as plant pots - perhaps not the most fitting end for a work of craftsmanship, but practical and more dignified than firewood.

A Note on the Maturation of Spirits in Oak Barrels

The chemical processes behind maturation of spirits in oak are at least as complex as they are for wine, but even more fundamental to the end result. In his excellent guide titled "Appreciating Whisky", Phillip Hills, founder of the Scotch Malt Whisky Society writes:"[Barrel] maturation is easily the most important part of the [Scotch] whisky production process as regards flavour. A malt whisky acquires more than half of its flavour during maturation; some would say as much as 80 per cent of the final flavour of the spirit comes from the cask."(20)

Hill's American counterparts would agree."The barrel is critical in the production of bourbon," says Fred Noe, bourbon ambassador and direct descendant of Jim Beam himself."Also, it's the law." Bourbon must be aged for a minimum of two years, and-critically for the cooperage industry-this must be done in new, unused oak barrels. As with other types of whisky, providing that no caramel is added,"one hundred percent of the colour comes from barrels,"Noe says."And it greatly mellows the bourbon."

After the staves are assembled, the open-ended barrel is set over a gas flame for up to one minute. This chars rather than toasts the inside and leaves it sooty black. Like wine makers, bourbon makers order their barrels according to how deep a char they need for their product. Noe says that Jim Beam uses a number four, the deepest char, which leaves a crackled, alligator-skin pattern inside the barrels.(21) "When they char the inside of that barrel,"he explains,"the natural sugars in the wood come to the charred area, and a caramelized layer sets up right where the char begins and the wood ends."(22)After the barrels are filled with whiskey-called "white dog" when fresh out of the still-they're rolled into the warehouses, where they age for 2 to 20 years (and often much longer for European Whiskies). Depending on the environment, the type of cask, its size, warehouse temperature and humidity, reactions proceed in differing degrees. In Bourbon country, sun heats the warehouses and night cools them, and this cycle causes the whiskey to expand and contract, passing back and forth through the charred oak. This process triggers a complicated interaction of flavours between the spirit and the wood, softening the new whiskey while lending it complex notes such as vanilla, caramel and spice. Given the variables involved, it's no wonder that the resulting spirit can be highly varied, so necessitating the blending of different barrels.

After been used just once to mature Bourbon, the barrels are shipped overseas where they are reused over and over again to make Tequila, Rum and European style whiskies. Lover's of Scotch or Irish whiskey have Kentucky Bourbon and American white oak barrels to thank.

The optimum period for the barrel maturation of spirits is to some extent a matter of taste and type, however, for Scotch whiskies, the consensus seems to be around 12 to 15 years, and even less for bourbon whiskies. At greater ages many whiskies (and other spirits) become unpleasantly woody, yet others can go on to reach fifty years or more and remain undiminished. Because some spirits mature faster than others depending upon a host of variables, it is only sensible that distillers and blenders concern themselves more with balance and maturity than age for the sake of age.

For further reading on this subject we recommend the section on "Maturing Whisky" in 'Appreciating Whisky', Phillip Hills published by Harper Collins, 2002.

* The barrel's sturdiness was perhaps most dramatically demonstrated in the many ill-conceived efforts to survive trips over Niagara Falls in one. In October 1901 Annie Edson Taylor went over the falls in a specially built barrel that was four and a half feet tall and three feet in diameter and fitted out with leather harnesses and cushions. She survived with a few bruises. Barrel and Box, a publication for manufacturers of packaging, noted that "while we are pleased with the ability of our coopers to make a barrel that will stand the racket, still the lady ... ought to have been spanked and put to bed for taking such a foolish trip." - AmericanHeritage.com Invention and Technology Magazine. "The Brilliance of the Barrel". Wayne Curtis, Spring 2006 Volume 21, Issue 4

** There is little agreement as to what point in history the barrel was conceived. Its basic concept can be seen in ancient Egyptian drawings as early as 2690 BC. Tapered tubs or buckets are depicted being used to transport wheat, however, they lack the characteristic "belly" and seal of later barrels. One can imagine how they might have progressed to staves forced together with wooden hoops but they never did, and probably for good reason. In such an arid country, barrels would have been ill adapted - they fall to pieces if neglected or left empty for a very short period in such climates. - So observed John Gardner Wilkinson in his "Manners and customs of the ancient Egyptians" 1837.

*** The Roman writer Strabo, writing in AD21, mentions wooden casks and describes the Celts as 'fine coopers', adding that they use pitch to stop leaks.

****The word "cooper" originates from the barrel makers of Illyria and Cisalpine in Gaul. Wine stored in wooden vessels was then called "cupals," and the maker was a "cuparius." If your surname is "Cooper" or "Hooper" it's more than likely that some of your ancestors were once employed in the craft.

+ These include: Q. prinus, Q. bicolor, Q muehlenbergii,Q stellata, Q. macrocarpa,Q, lyrata and Q. durandii.

++ Recently, proponents for an alternative American species, Quercus garryana, or Oregon White Oak, have emerged who swear by its similarity to French oak.

1. The Oxford Companion to Wine. Oxford University Press, 1994.

2. AmericanHeritage.com Invention and Technology Magazine. "The Brilliance of the Barrel". Wayne Curtis, Spring 2006 Volume 21, Issue 4

3. The Flavours of American Oak, By Dr. Tom Cottrell. Wine Business Monthly, November 1, 2003

4. Some technical data adapted from 'Oak Aging of Red Wine', 'Wooden Cooperage' & 'Oak Wood Composition' - three articles by Dr. Murli Dharmadhikari - Iowa State University 2007

5. Barrel Construction information partly sourced from the French cooperage, Seguin Moreau.

6. See www.worldcooperage.com for examples, a Napa Valley based company founded in 1912.

7. Ibid

8. The Australian Wine Research Institute. Oak Volatiles. www.awri.com.au

9. ETS Laboratories, Technical Bulletin Oak Aroma Analysis 2001

10. Oak Aging of Red Wine* By Dr. Murli Dharmadhikari - Iowa State University 2007.

11. Influences of Oak on Making and Maturing Wine, Christy A Canterbury. Wine Business monthly, December 2005.

12. Enology International. Rethinking American vs. French Oak. Jordan P.Ross. 2002

13. Corrina Rayment is winemaker at Oliver's Taranga vineyards. In 1997, Corrina was granted a Scholarship from Southcorp Wines and Adelaide University to study for a year at the University of California- Davis, after which she returned to Australia to work for Southcorp Wines on their Winemaking Graduate Program. During her work with Southcorp, Corrina has also been making the Oliver's Taranga Wines a local contract winery and she has been responsible for the development of the Corrina's Blend and the HJ Reserve Shiraz.

14. Andrew Sutherland Smith is a fifth generation wine maker to Rutherglen, who's family owned the famous All Saints Winery from 1864 to 1988. Andrew is a graduate and scholar of Charles Sturt University and has worked extensively throughout the Australian wine industry. Since 1981 he has worked for companies including Seppelts, Charles Sturt University (Ron Potter Scholar), Yellowglen, Mildara, Stanley, McWilliams and All Saints. Warrabilla Wines was established in 1991 by Andrew. Whilst developing Warrabilla Wines, Andrew also worked for Chambers Rosewood Winery and Fairfield. Today Andrew's wines reflect his enormous energy and determination to reassert the Sutherland Smith's as a great Australian winemaking force. Australian wine writer James Halliday seems to agree, giving the winery a five star rating being only one of two table wine makers in the North-East to receive the accolade - the other is Giaconda.

15. 'Oak Flavorings. With cost a concern, winemakers find detours to new barrel flavors'. Wine Spectator magazine, Daniel Sogg September 30, 2002 issue

16. Ibid

17. Peter Gago joined the then Penfolds Wines Pty Ltd in 1989. He started his tenure making sparkling wine, then reds, and served as Penfolds Red Wine Oenologist before being appointed Penfolds Chief Winemaker. In July 2002, Peter took over the mantle from his long-time friend and colleague, John Duval, making him the fourth winemaker to be responsible for Penfolds' icon wine, Grange. A natural educator, Peter has co-authored three books with Dr Patrick Iland: "Discovering Australian Wine - A Taster's Guide" 1995, "Australian Wine - From the Vine to the Glass" 1997 and "Australian Wines - Tastes and Styles" 2003.

18. The description of slow gas osmosis in wine barrels is adapted from "How Wine Barrels Work", A.E. Flecknoe-Brown. October 2002. The text he cites refers to Margalit, Yair - "Concepts in Wine Chemistry" 1, 1997. 1st Edition.

19. Oak Barrel Alternatives in Winemaking, Richard Gawel, Winestate Magazine August 2002

20. Appreciating Whisky, Phillip Hills. Harper Collins 2002

21. AmericanHeritage.com Invention and Technology Magazine. "The Brilliance of the Barrel". Wayne Curtis, Spring 2006 Volume 21, Issue 4

22. Ibid.

23. Wine: A Scientific Exploration, By Merton Sandler, Roger Pinder. Published 2003 CRC Press