Beans & Nuts

Ingredients: Beans & Nuts

Ingredients: Beans & Nuts

Our daily ritual of making tea or coffee involves a process of infusion which as we have said earlier is one of the basic processes involved in the extraction of essential oils. It is therefore a fairly natural step for liqueurists to use these raw materials, the basis of our everyday beverages, as flavourings for a whole list of excellent liqueurs.

Coffee gives us probably the widest field for exploration and experimentation because there are so many styles available. Its name gives an indication of its antiquity as a man made beverage going back as it does to early Arabic times when it was known as Qahwah. The ancient Turks called it Kahveh and it was introduced into Europe during the 17th Century. It comes from the evergreen tree botanically known as Coffea Arabica which is now cultivated in most tropical countries although we in Australia draw our supplies chiefly from Papua New Guinea, Brazil. Jamaica and Turkey. The bean is the seed of the tree and, when first picked, is surrounded by a bright red jelly-like fruit called a cherry. This fleshy covering must first be removed by a "wash or "dry" process to leave the raw beans which are later roasted to the desired degree. During roasting some of the components of the green bean are decomposed and the original bitterness is dissipated. As the temperature of the roast approaches 400'F. the beans begin to pop and expand to nearly twice their original volume and by this time much of the flavour has been developed. Roasting is stopped abruptly when the desired flavour peak has been reached by quenching in cold water followed by rapid air cooling. We determine the degree of roast solely by watching the colour of the beans. The darker the roast, the stronger will be the resulting beverage. For our purposes roasting must be done immediately prior to grinding and maceration because roasted coffee can lose much of its flavour and aroma relatively quickly if left exposed to the air. Like tea, the best coffee in the world comes from the highest elevations and a Coffee taster, to be proficient, must bring to his vocation years of experience and a highly developed sense of taste and smell, the same attributes of the Master Liqueurist. Coffee liqueurs are frequently based on Rum as in our "Coffee Brazil" although neutral spirit may also be used where it is desired that only coffee will dominate in the aroma and flavour. "Kahlua", originally from Mexico but now made in Denmark by Peter Heering is an extremely good coffee liqueur with a clear light coffee style. "Tia Maria" is made from Jamaican Blue Mountain Coffee. This is the most notable thing about coffee liqueurs - they all differ markedly from each other depending on what the liqueurist is attempting to achieve. There is a Russian liqueur Okhotnichya, or Hunter's brandy, which uses very high strength Russian brandy as a base spirit and which has coffee as one of its contributing flavours. But since other flavours in the liqueur include aniseed, cloves, citrus, ginger, galingale, juniper and pepper, it is not really feasible to call it a coffee liqueur!

Cocoa is in many ways similar to coff fee and is grown in roughly the same locations around the world: in the tropical zones. The cacao bean, the seed of tropical trees of the species Theobroma Cacao, played a vital part in the Aztecs' culture. They believed it to be of divine origin and that one of their most ancient God heroes, Quatzacatl, had brought the seeds from Paradise to cultivate on earth. The eating of the fruit was thought to have given him universal wisdom. The beans are borne in a pod which after picking is slashed open and the beans. surrounded by a sweet pulp, scooped out. This pulp is difficult to remove and fermentation is needed to reduce it to a manageable state. During the fermentation the temperature of the beans may rise to 115'F and this has a very great and beneficial effect on the colour, texture and flavour of the finished beans. The colour changes, in fact, from a creamy white to a brownish red, the flavour softens and its original bitterness almost disappears. Following fermentation the beans still contain a deal of moisture and this is reduced from 33% to about 6% by sun and air drying. During this drying further chemical changes occur which further reduce the astringency of the beans.

Cocoa is in many ways similar to coff fee and is grown in roughly the same locations around the world: in the tropical zones. The cacao bean, the seed of tropical trees of the species Theobroma Cacao, played a vital part in the Aztecs' culture. They believed it to be of divine origin and that one of their most ancient God heroes, Quatzacatl, had brought the seeds from Paradise to cultivate on earth. The eating of the fruit was thought to have given him universal wisdom. The beans are borne in a pod which after picking is slashed open and the beans. surrounded by a sweet pulp, scooped out. This pulp is difficult to remove and fermentation is needed to reduce it to a manageable state. During the fermentation the temperature of the beans may rise to 115'F and this has a very great and beneficial effect on the colour, texture and flavour of the finished beans. The colour changes, in fact, from a creamy white to a brownish red, the flavour softens and its original bitterness almost disappears. Following fermentation the beans still contain a deal of moisture and this is reduced from 33% to about 6% by sun and air drying. During this drying further chemical changes occur which further reduce the astringency of the beans.

Everyone is familiar with the coffee bean I imagine, but few with the cacao bean. This is a flattish, smooth brown bean approximately 1.5 inches long, 0.5 inch wide and 3/8 inch thick. It is roasted immediately prior to use and then cracked and winnowed to remove the hard thin outer shell to leave the 'nib' or inner kernel. The nibs are pressed and ground to give a paste which contains 55% of cocoa butter from which chocolate is made. The majority of the cocoa fat or butter can then be extracted to leave "dry" solids or Cocoa powder.

We use this powder for our infusion process to produce our Creme de Cacao which can be made colourless or brown. The finesse in this case is concerned with the refinements employed, the purity of the vanilla added and the overall balance of the blend. You may notice on some Creme de Cacao the word Chouao (pronounced CHOO-WOW). When cocoa was at the height of its vogue in the 1800's, the finest beans procurable were grown in the Chouao Valley near Caracas in Venezuela. The valley is now a suburb of Caracas and Cocoa no longer graces its slopes. Chouao has now come to be used as a generic term for all Venezuelan beans which are still most highly regarded. Like coffee the flavour of cocoa varies depending upon the variety and the climatic conditions in which it is grown. The areas in which it is grown usually lie within the warm moist climate, 20' N or S of the equator. However large quantities come from Accra on the African Gold Coast. Ceylon and Java produce beans of the highest quality while the West Indies' beans have very good flavour often with an aromatic bouquet. We obtain most of our supplies at the moment from Venezuela and Sierra Leone; both of which sources provide us with high quality beans with high aroma and good chocolate extraction.

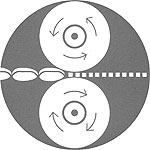

The process of extraction of flavour is shown in the diagram in pages 36 and 37 but, to expand slightly, what occurs is that the nibs of cocoa are ground then mixed with alcohol and water and left to stand. The mixture is agitated twice daily for three days following which it is filtered and the remaining mash mixed with water and distilled to give a cocoa distillate which is added to the first filtration. A further addition of dry ground nibs may then be put into the filtrate and again stood and agitated for three days. This constitutes a continuing process of maceration, filtering, additional maceration, filtering and finally concentration by evaporation or, indeed, fractionation as explained at the end of the whole process.

Finally I should mention one particular liqueur which is based on Chocolate and that is Chocolat Peppermint. I will describe it more fully in a later section, but we think that the combination of both Peppermint and Chocolate in the one liqueur is most appropriate, not to say inspired. Our natural modesty however will ask you to make your own assessment.

Vanilla is not truly a bean although we always describe it as such. It is in fact a pod; the outer covering for beans. It is the fruiting body of a tropical orchid, Vanilla planifolia, first found in Mexico. The Totonaco Indians watched many strangers, after stout Cortez, take cuttings of their vines and they smiled to themselves because they knew, from long experience, it would not prosper elsewhere or, if it did, it would not yield fruit. It was not until 1836 that an astute botanist realised that, because of the peculiar floral structure of the Vanilla orchid, it was a virtual impossibility for any but a particular tiny bee, native to the producing areas of Mexico, to penetrate to the stigma of the flower and cause pollination to occur. About five years later, on the Island of Reunion in the Indian Ocean, a former slave, Edmond Albins, developed a reliable method of pollinating Vanilla by hand. He used a short wooden spike to penetrate the labia of the flower and deposit pollen from the stamen onto the cryptic stigma.

Vanilla is not truly a bean although we always describe it as such. It is in fact a pod; the outer covering for beans. It is the fruiting body of a tropical orchid, Vanilla planifolia, first found in Mexico. The Totonaco Indians watched many strangers, after stout Cortez, take cuttings of their vines and they smiled to themselves because they knew, from long experience, it would not prosper elsewhere or, if it did, it would not yield fruit. It was not until 1836 that an astute botanist realised that, because of the peculiar floral structure of the Vanilla orchid, it was a virtual impossibility for any but a particular tiny bee, native to the producing areas of Mexico, to penetrate to the stigma of the flower and cause pollination to occur. About five years later, on the Island of Reunion in the Indian Ocean, a former slave, Edmond Albins, developed a reliable method of pollinating Vanilla by hand. He used a short wooden spike to penetrate the labia of the flower and deposit pollen from the stamen onto the cryptic stigma.

The vines are not difficult to establish from cuttings planted in the loose, damp and very rich soil and humus near to support trees. They will normally flower two years after planting and the flower buds take 5 or 6 weeks to develop to the flowering stage. The flower which is very beautiful, lime-yellow vath a satin texture to the petals, will open to the world one morning and by night-fall be withered and gone. The pollination must be successfully done in the first few hours of its life. Beautiful though the flower may be, it has no perfume. All of the aroma and flavour have been reserved for the bean which is perhaps fortunate for mankind.

The French developed the production of Vanilla, first at Reunion and then at Tahiti and accounted for 75% of the world production in 1968. However the Mexicans were not slow to profit from example and soon left the diminutive bee to his own devices and employed Albins' splinters to good effect. To be sure of bringing only the best full sized pods to maturity only about 50 flowers are pollinated on each vine out of a potential thousand or more. When the pods are at their optimum development they are picked and sun dried for many weeks on blankets and covered at night so that the water content can be reduced as much as possible without disturbing the essential oils which are the source of the beautiful sweetness and delicate perfume we use to such good effect in many of our liqueurs. When I tell you that about 80% of the original weight of the pods is lost in the curing and bearing in mind the laborious processes of cultivation, pollination, hand picking and the rest you may understand why vanilla is so expensive. The percentage yield of major flavour ingredient from vanilla is 0.5 to 3% while cocoa is 50%. Extraction is done by a maceration with alcohol and subsequently as described below. There is a French Liqueur, Creme de Vanille which relies solely on Vanilla for its flavour but mostly we use it in combination with other flavour sources to give an extremely delicate perfume and a luscious soft sweetness.

Nuts are our next raw material. Chiefly the sweet edible nuts; Almonds, Hazels, Walnuts, Pecans, Pistachios, Brazils and Coconuts. However some bitter types are also used; bitter almonds for instance and the kernels of the stone fruits; peaches, apricots and cherries. For the most part the sweet nuts do not usually yield an oil and a flavour which is sufficiently intense or sufficiently aromatic for us to use, unsupported, in a liqueur. Exceptions to this are the very excellent Cremes de Noyau of Europe which have a delicate but definite almond character often supported by peach and apricot kernels, (these latter are termed "Drupe" fruits - a description I find unfortunate and avoid using!) and also the Cremes de Noisettes, which employ nuts of several descriptions, Hazel and Walnuts particularly. There is an American liqueur which combines chocolate with a very excellent toasted almond flavour which seems to bring out the nuttiness in a most dramatic way.

However we mostly use the extracted oils of nuts in a blending capacity; to lend depth, sweetness and nuttiness to fruit based liqueurs. I mentioned coconut earlier and it is interesting, to me at least, that this nut has not been used to the extent it possibly could be. We all know its flavour from biscuits and cakes and it might be said it was somewhat too bland and too indeterminate in flavour. I am not so sure about this and since it grows almost on our doorstep, I will be thinking about it. Like vanilla, flavour from nuts is extracted by first crushing and grinding the shelled nuts to a meal which is then soaked for some days in a light mixture of alcohol and water. Following this maceration it is strained and the remaining mash of nuts is pressed gently to express the last of the liquid and any retained oil. Finally the strained and pressed liquid is taken to the stills and concentrated. In some regards liqueurs made from Beans and Nuts are the simplest to make since they rely on one basic ingredient for their flavour. But simplicity is often the most elusive and difficult of attainment in the making of liqueurs.

Extraction from Beans & Nuts

The various beans and nuts are thoroughly cleaned in the country where they were grown to remove any adhering dirt, dust and unwanted vegetable material.

CRUSHING. In the case of coffee and cocoa the beans are roasted to the degree required before going to the crusher. Other nuts, such as Almonds, Hazel Nuts and others which are edible without cooking merely have their outer shells removed. The Crusher breaks the beans or kernels into a coarse meal so that the greatest surface area is exposed to the solvent. Vanilla pods, being somewhat leathery in texture, are slashed.

MACERATION AND INFUSION. The crushed material is next 'transferred to a perforated metal basket which is encased in a sealed stainless steel vessel. A warmed charge of solvent, pure alcohol, is then pumped into the vessel in such a way as to mingle with the crushed meal. By a process of surging and rousing the solvent penetrates deep into the particles and extracts all the flavour compounds from the Beans and Nuts.

EVAPORATION. From the macerating vessel the solution, now saturated with flavour, may be taken to a vacuum evaporative still. Here gentle heat is applied to remove the volatile solvent and to leave behind a heavy concentrate containing all the flavour and much of the colour of the original ingredients. This is called an "oleo-resin" and can form the basis for a liqueur without further treatment.

FRACTIONATION. If however we need to be more selective, and we frequently do, in the types and qualities of flavours, the macerate will be taken to a Fractionating Still where some of the solution is distilled over and flavour fractions can be separated out. These will frequently have all, or most, of their colour removed and will end up as highly concentrated extremely volatile flavour fractions which are much reduced in bulk. They can then be available for compounding into liqueurs.